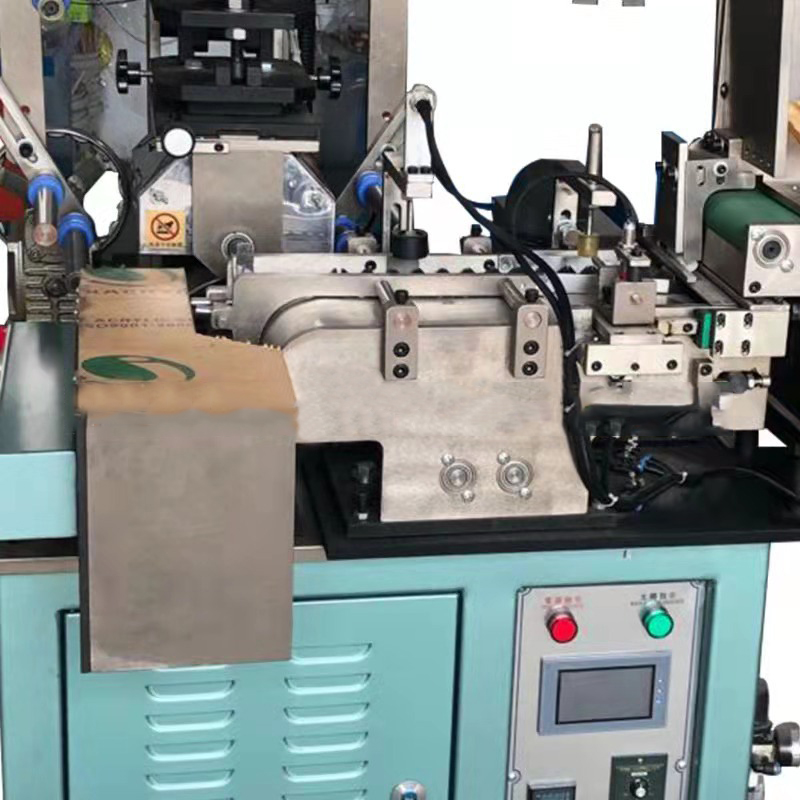

Automatic pen heat transfer printing machine

Contact Us

Inquiry

This machine is designed as a cylindrical product, with PLC precise control and positioning, human-computer interaction interface, simple operation, automatic loading and unloading, automatic steering, high work efficiency and good stability. Suitable for all kinds of pen holders and cosmetic bottles, etc.

heat transfer printing process

The thermal transfer machine is a new type of printing machine that transfers the pre-printed thermal transfer film to various substrates by heating and pressurizing the pre-printed thermal transfer film.

It has high productivity, significant economic benefits and more beautiful appearance. It is a surface printing process.

Ideal equipment for the industry. It can be hot stamped on the flat and curved surfaces of plastic, wood, metal, leather, glass and other products.

Feature

- Fully automatic feeding or conveyor belt feeding, suitable for mass production of stationery and cosmetic pipe fittings

- Adopt stepper motor for paper delivery, automatic pre-positioning of precision, two sets of servo photoelectric eye positioning systems for front and rear, left and right

- Using Japanese divider, Italian tooth box, mechanical linkage

- Automatic electrostatic dust removal before and after hot stamping

- Automatically rewind the film, with built-in five-digit counter

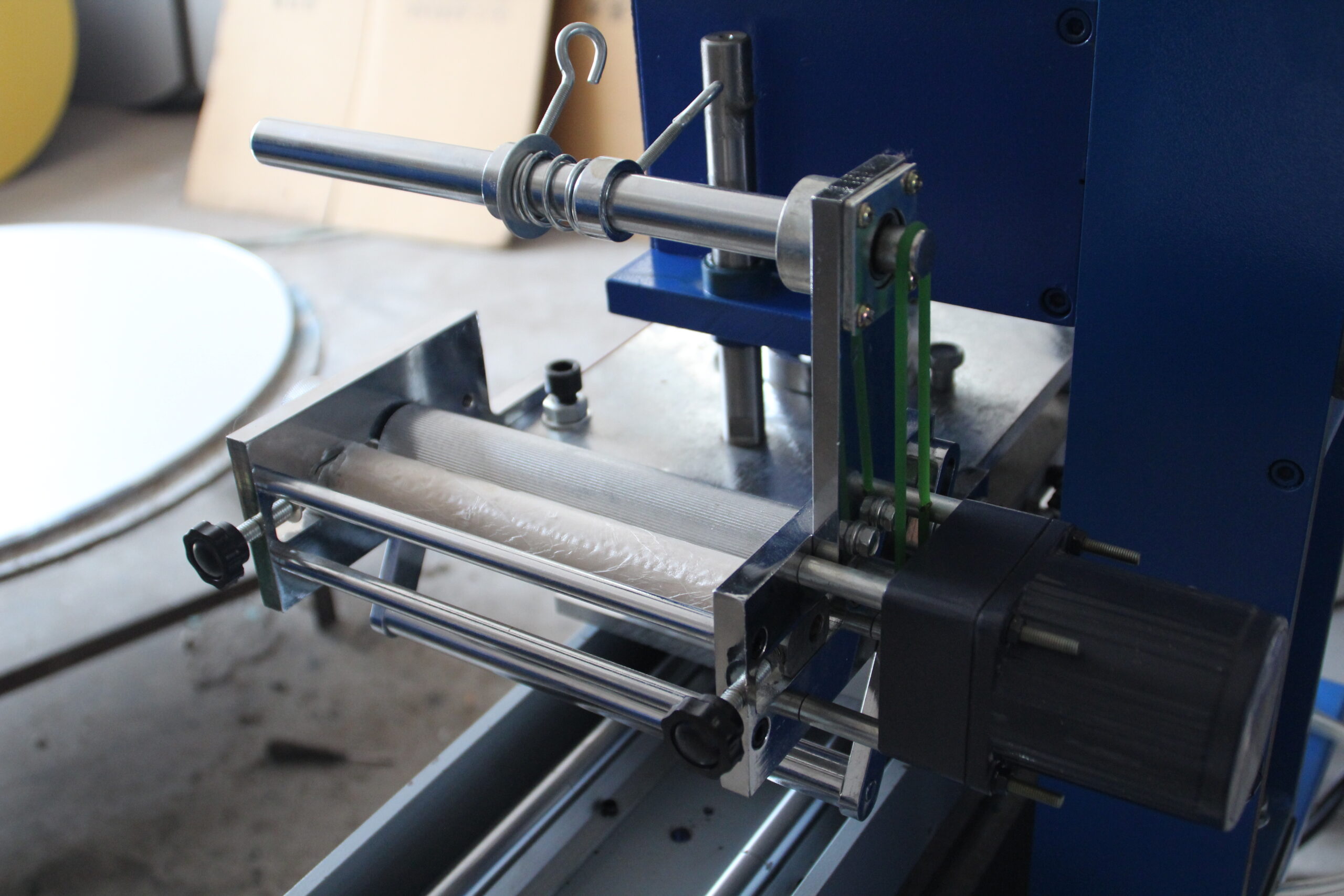

- The rubber roller rotates for heat transfer hot stamping, the height and front and rear slope of the hot stamping head can be adjusted, and the stamping pressure, temperature and speed can be adjusted.

- Equipped with high-precision photocells (electric eyes) to track and control the transfer paper with contacts. The timed feeding method is adopted for the transfer paper without contact.

- PLC control, programmable terminal LCD display, built-in various operation control programs and adjustable parameters

Parameter

| Operate | Full automatic |

| Application | Pen,ect round product |

| Printing speed | 40-60pcs/min |

| Suitable item diameter | 4-30MM |

| Suitable item length | 60-200MM |

| Power | 2.6KW |

| Glue roller size | φ180×102mm |

| Stamping item size | φ8-20mm×170mm(can be customized ) |

| Stamping temp | Room temp 280 Celsius |

| Air pressure | 5-7bar |

| Max stamping pressure | 2138(7bar) |

| Max stamping speed | 2000pcs/hr |

| Voltage | 110/220V 60/50Hz |

| Heating power | 1200W |

| Air consumption | 281L/min |

| Machine size | 1750×1100×1050mm |

| Machine weight | 480kg |

Application

Suitable for daily necessities, cosmetics, plastic toys, plastics, stationery, tableware, electronic appliances, building materials, kitchen and bathroom, home improvement materials, food, medicine and other outer packaging.

Applicable materials: plastic products (ABS/PP/PE/PS/PC/PVC, etc.) wood, glass, metal, etc.

Advantages of transfer process

- The color pattern is formed by one-time transfer printing, no need for color registration, and the loss is reduced;

- The whole surface transfer product, no ink residue, good compatibility.

- The process is simple, the process is few, the efficiency is high, and the simple equipment can also print the pattern;

- The processed products are bright, beautiful, bright in color, clear in pictures and texts, and increase the added value of the products.

Machine maintenance

① Before printing , clean up the sundries on the machine and wipe the machine clean. Lubricating grease should be added regularly to moving parts such as guide rails, guide posts, and bearings.

② The workpiece table is a key component that affects the printing quality. It prevents the impact of hard objects. During printing, the ink cannot be removed. Organic solvents such as Tianna water drip onto the work surface.

③ The electric control panel and buttons should be prevented from being damaged by direct or indirect contact with solvents such as Tianna water, boiled oil and water.

④ The frame paint is to keep the machine from rusting, to prevent damage caused by direct or indirect contact with solvents such as Tianna water, boiled oil and water.

⑤ Drain the sewage and dirt in the oil mist combiner in time. To prevent the pneumatic components from being fed into the normal operation, clean the cup body regularly, and add Peng 2 lubricating oil to the oil cup of the oil mist combiner.

⑥ When adjusting the restrictor valve, the tightening nut must be loosened before adjusting by hand. The handle screw on the machine is used for positioning. After firmly positioning, there is no need to tighten it with excessive force.

⑦ After printing, turn off the power/air source, clean the wire mesh, and keep it properly. Dust/pressure/hard object piercing.

TaoXing Company Introduction

Taoxing automatic screen printing machine video compilation

Service / FAQ

Guarantee

① We provide comprehensive one-stop services, customer training and satisfied after sales services.

② Online support, video technical support for troubleshooting manufacturing problems, engineers are available to service oversea as necessary.

③ Sold enjoy one year of free equipment warranty and lifetime technical support.

Guarantee for Delivery

Safety and fast logistic ensures the goods are delivered on the right time

1. Packing: Plywood Case for Each Machine

2. Payment terms: T/T (50% deposit to start the production, 50% paid before delivery)

3. Delivery date:60 business days after received the payment.

4. Departure of port: By sea from Shanghai or Ningbo

5. Delivery means: By sea by land

A: We are a professional manufacturing factory specialize in printing equipment with more than 20 years experience, committed to supplying our customer top quality and dedication to the constant improvements of quality, reliability, productivity and the competitiveness of our products and services.

A: Please send us an inquiry directly. We need to get specific details, such as material, size, color, thickness, quantity, etc.

A: Yes, we have a professional technique team, we could produce the machine depends on your requirements.

A: We accept TT/LC/PAYPAL/Western union, every payment term we can discuss.

A: All Taoxing products carry up to a full year warranty. Supply wearing parts with favorable price and long term after-sales service. We believe in total customer satisfaction, aside from our no-hassle guarantee.

Screen printing was a technique first used by the Chinese almost 2000 years ago. It is widely used at home and abroad. Chinese printing machine market has already become the focal point of the world have opened up. We have teams of experienced technical experts and professionals providing most professional and just-in-time technical consults and services, timely supply of spare parts in place.

If you are still confused how to start printing work, don’t worry, contact us and we will help you out!! No mater you are a green hand, we will train you up-to-date technology skills, and keep an eye on your business opportunities. Our friendly and professional team that is able to handle all your inquiries whenever you need.