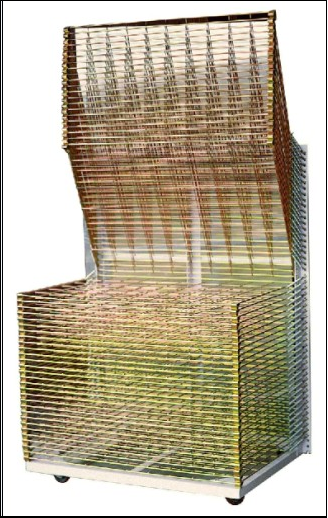

Application:

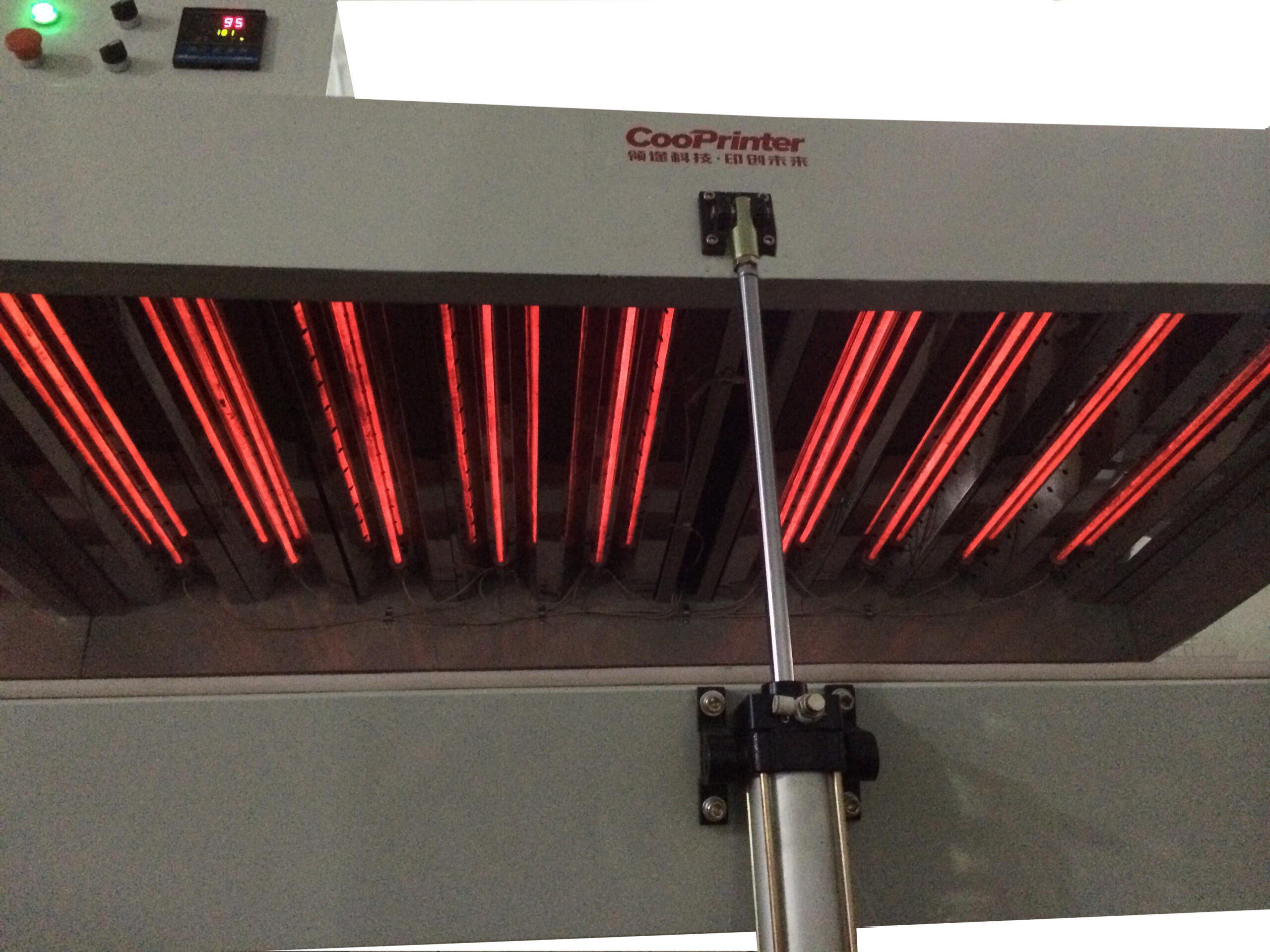

Mainly used for the flame treatment on the surface of the PP and PE plastic products, the plastic products after treatment by this machine, when printing, the printing ink can be more firmly attached to the printing items.

Features:

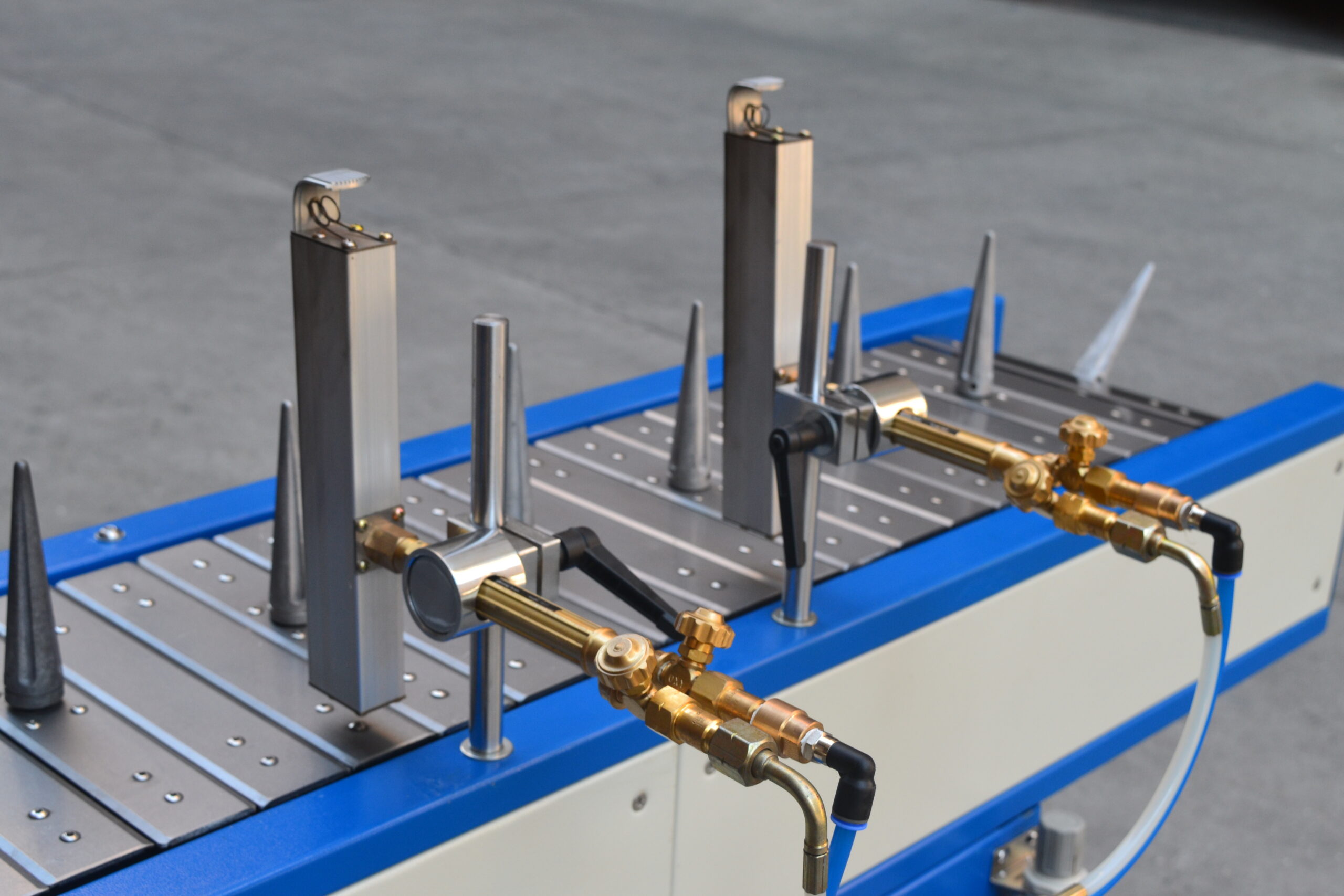

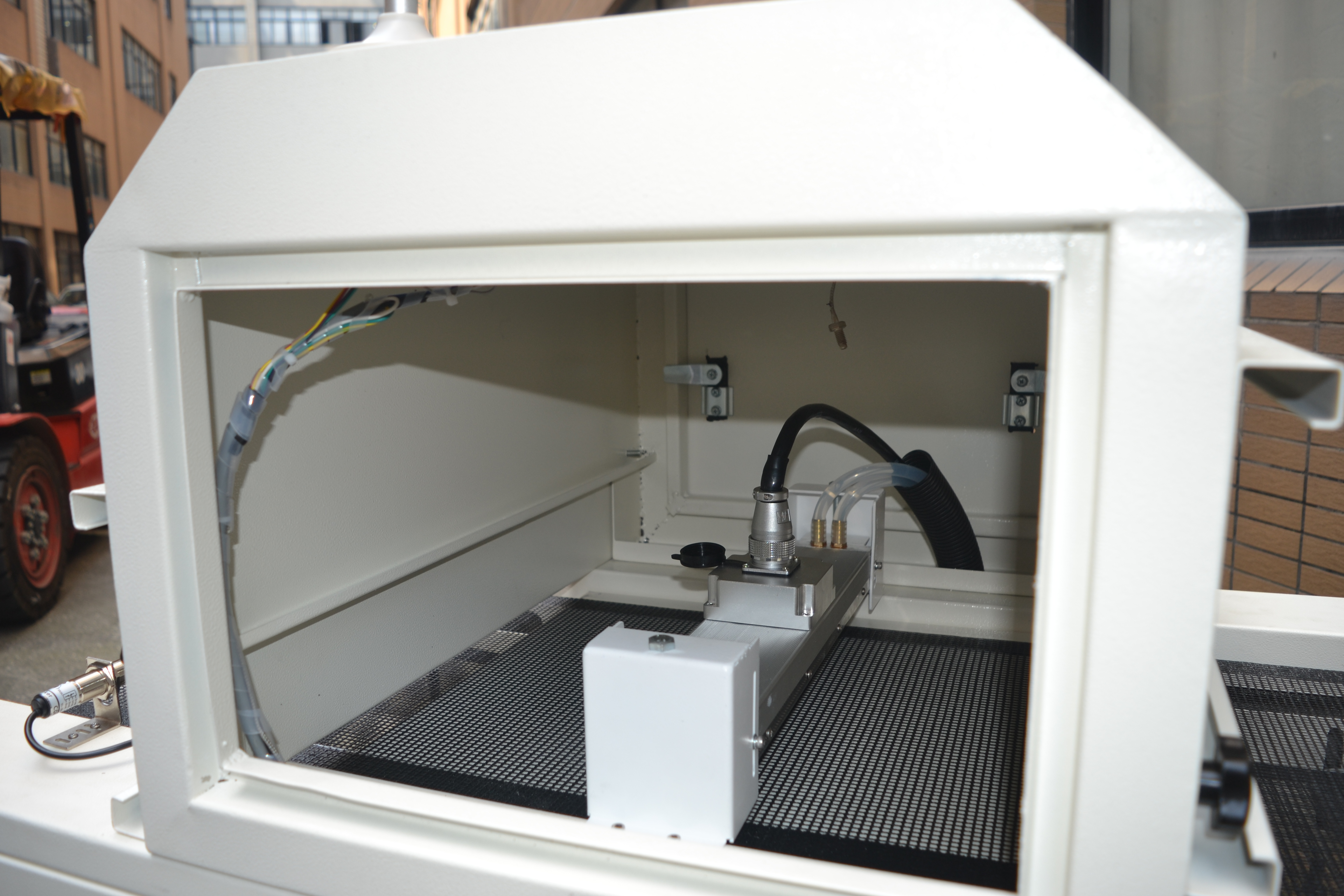

- Special disk type stations are installed for fixing cylinders. Sizes are adjustable and substrate loading as well as unloading easy;

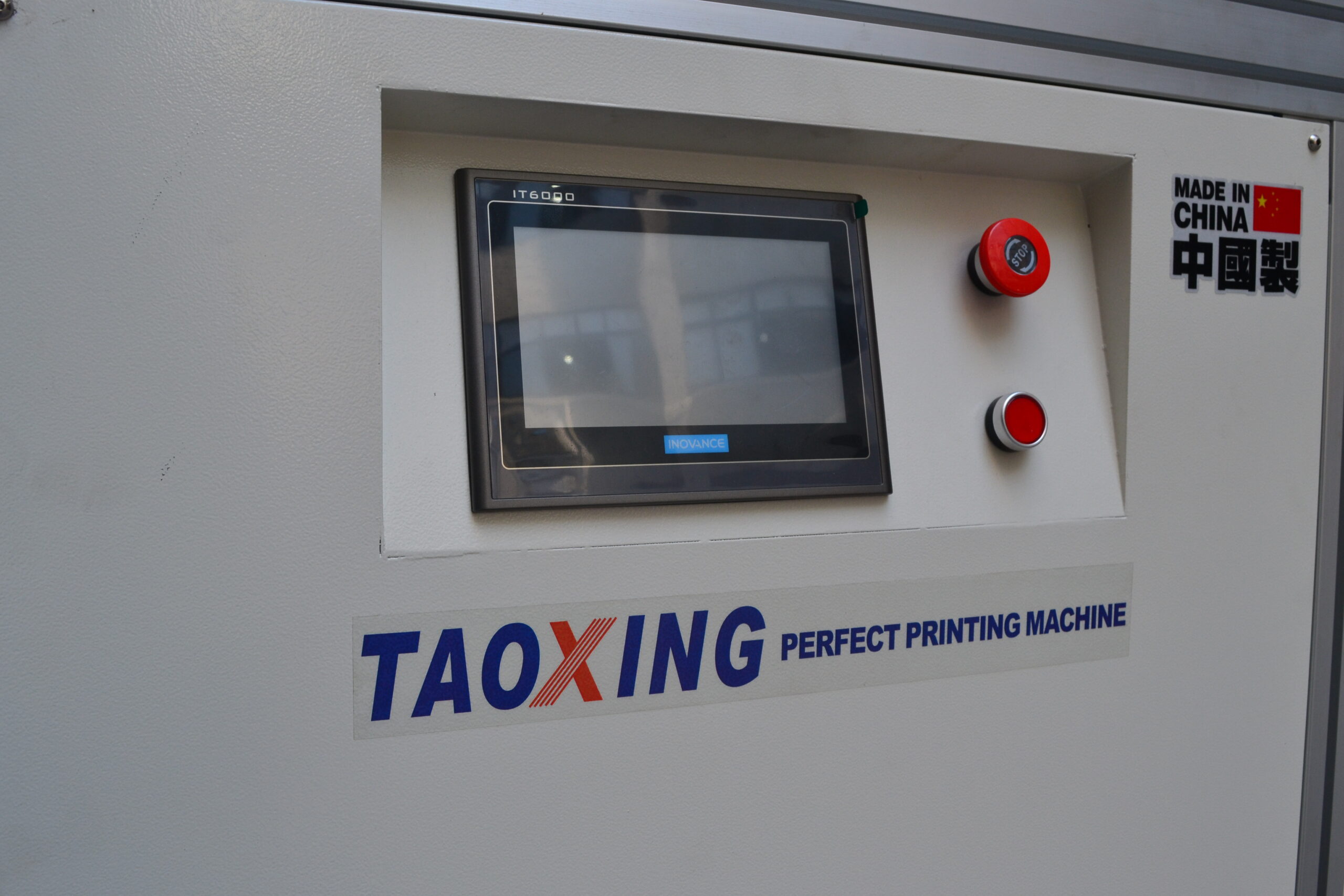

- In electrical control, advanced mini-motor is used with stepless change to meet the requirement of various substrate

- Unique designs of flame nozzle and distributor make fuel utilization rate high, so it is an evergy-saving product

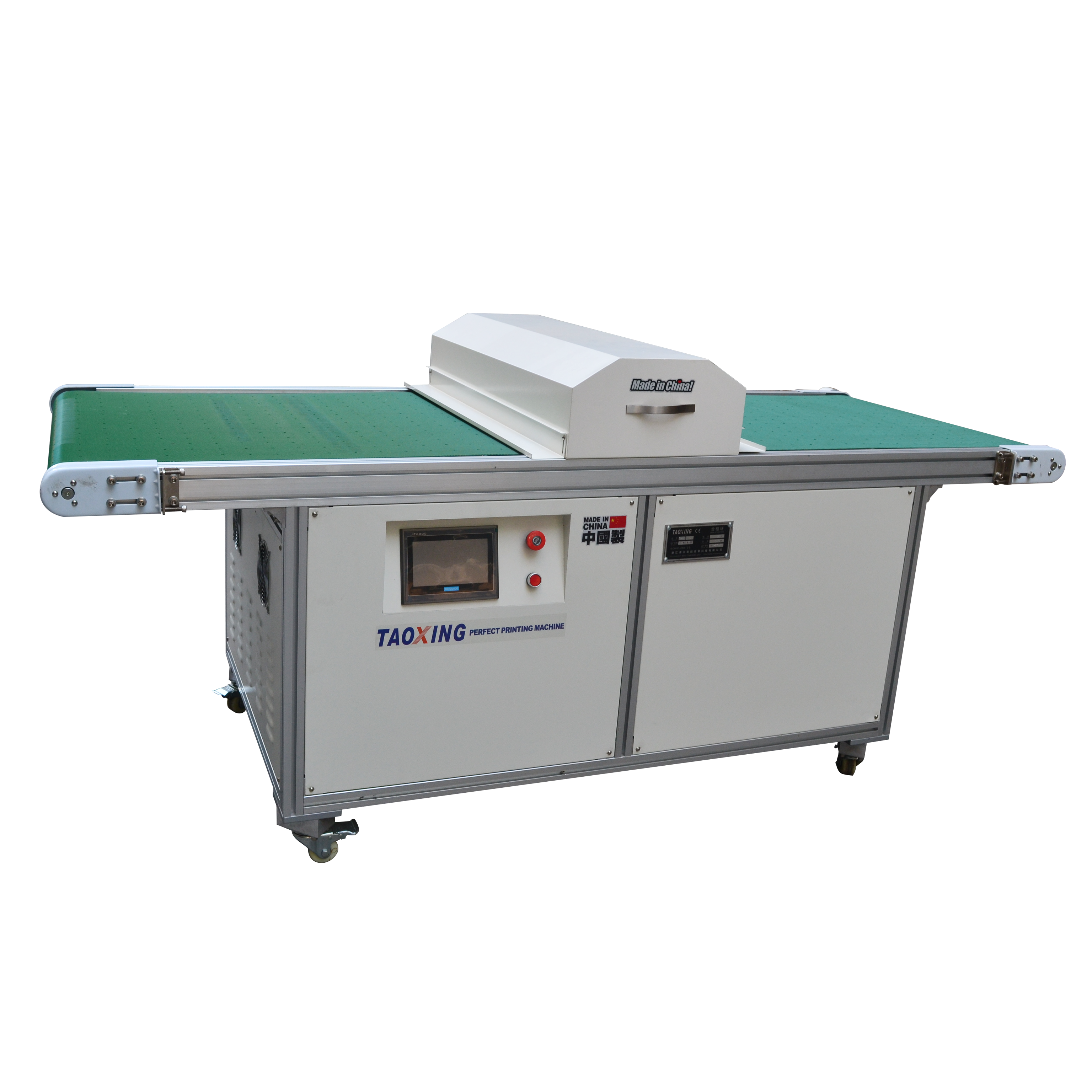

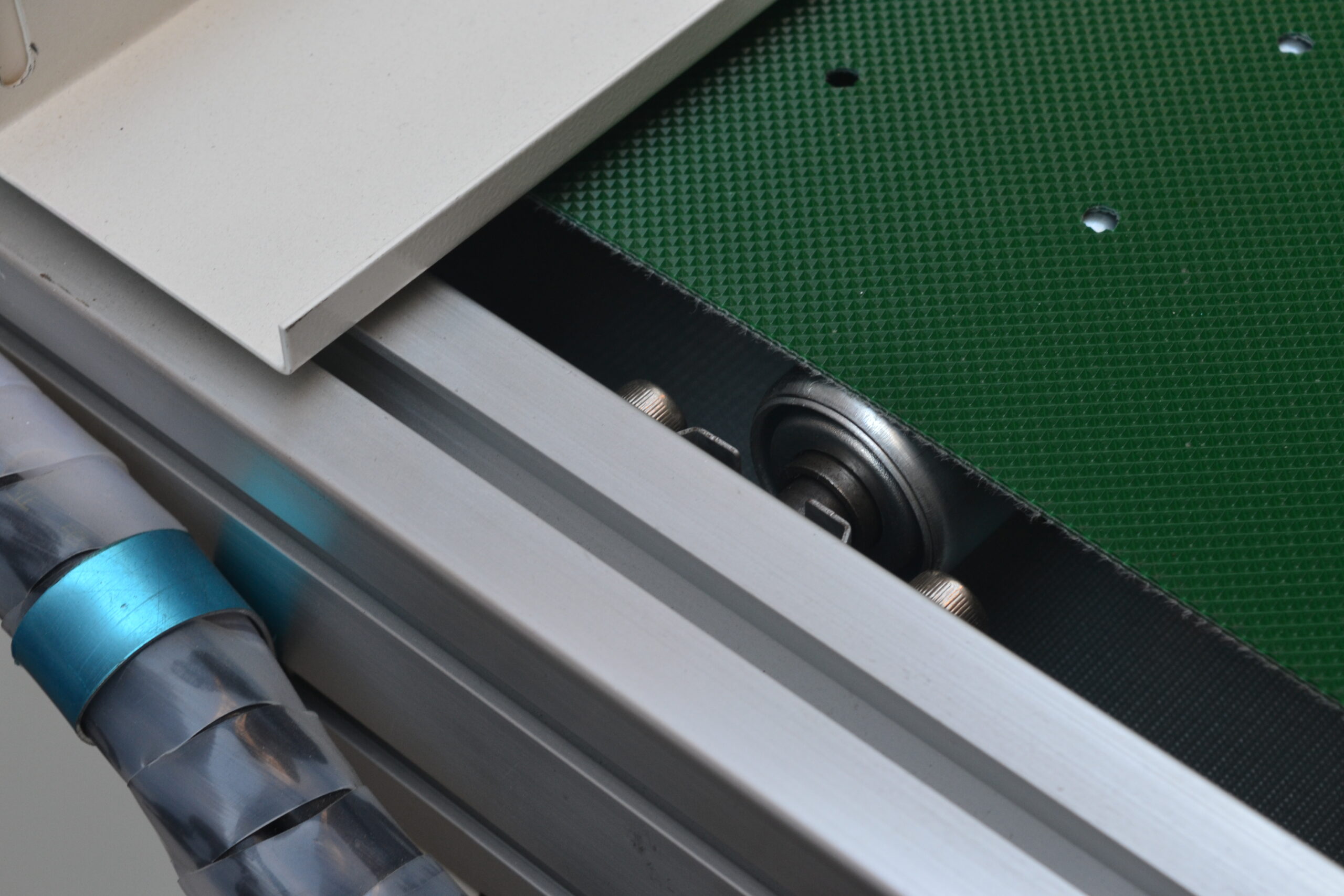

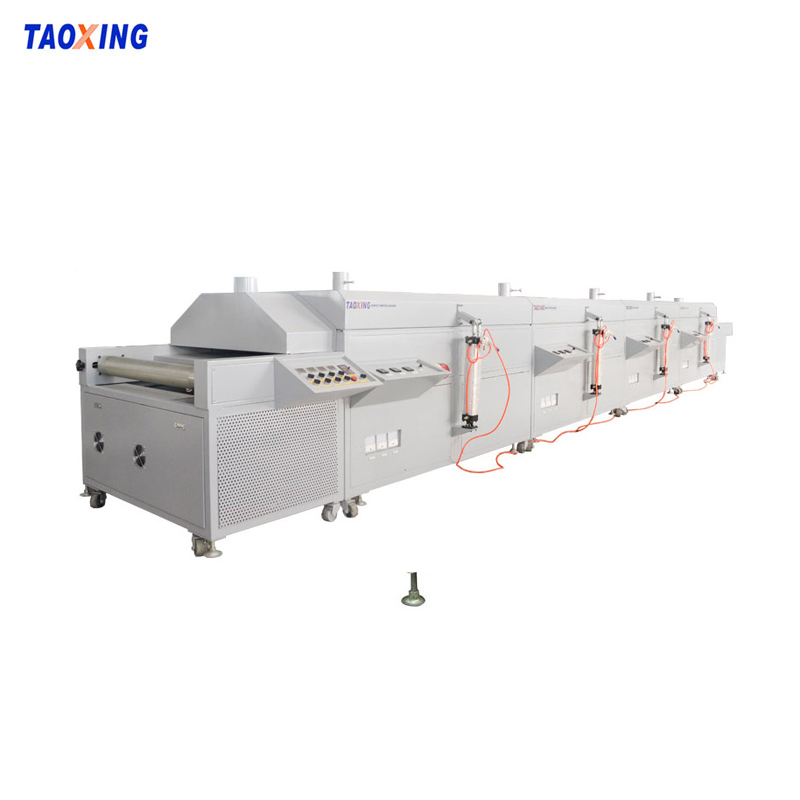

- Integral structure is novel, design suitable and operation easy. Roller wheels are installed at the foot to provide convenient movement.

Technical Parameter:

1: Frame width: 250mm; Combustion gas: standard petrolic gas;

2: Combustion-supporting gas: compression air with pressure 8KGF/cm2;

3: Power Supply: 220V/50Hz; Conveyor speed: 0~10m/min;

4: Speed adjustment speed: electronic step less change;

5: Conveyor size: 1830×360mm; Dimension: 1850×530×1200mm(L×W×H) Weight: 100KG

| Frame width: | 250mm |

| Combustion gas | standard petrolic gas |

| Combustion-supporting gas | compression air with pressure 8KGF/cm2 |

| Power Supply | 220V/50Hz |

| Conveyor speed | 0~10m/min; |

| Speed adjustment speed | electronic step less change |

| Conveyor size | 1830×360mm |

| Dimension | 1850×530×1200mm(L×W×H) |

| Weight | 100KG |

Notes: we are always improving and innovating in technology and quality. All machines can be designed according to those given parameters and requests from customers. Parameters and instruction in this catalog are only for reference.