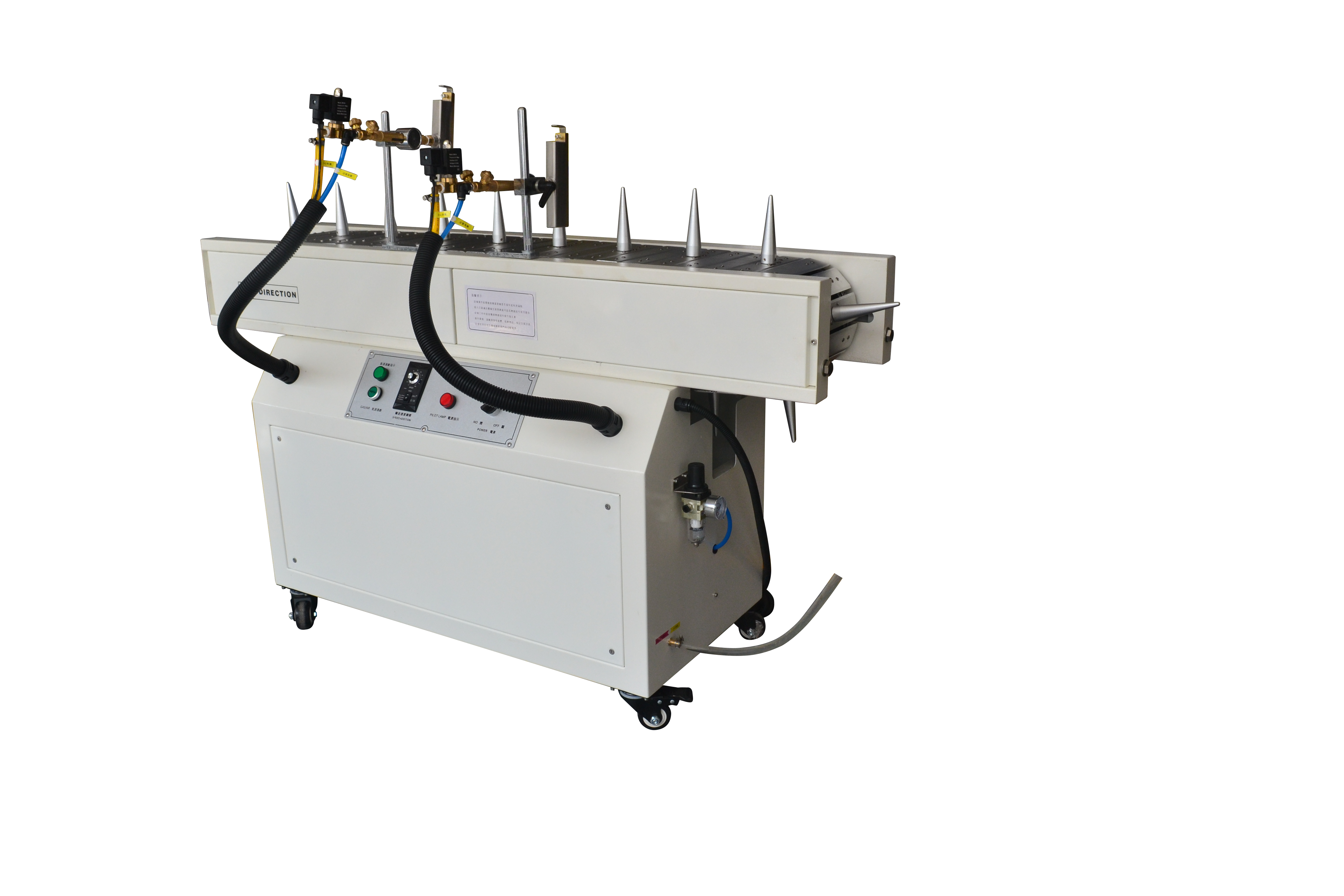

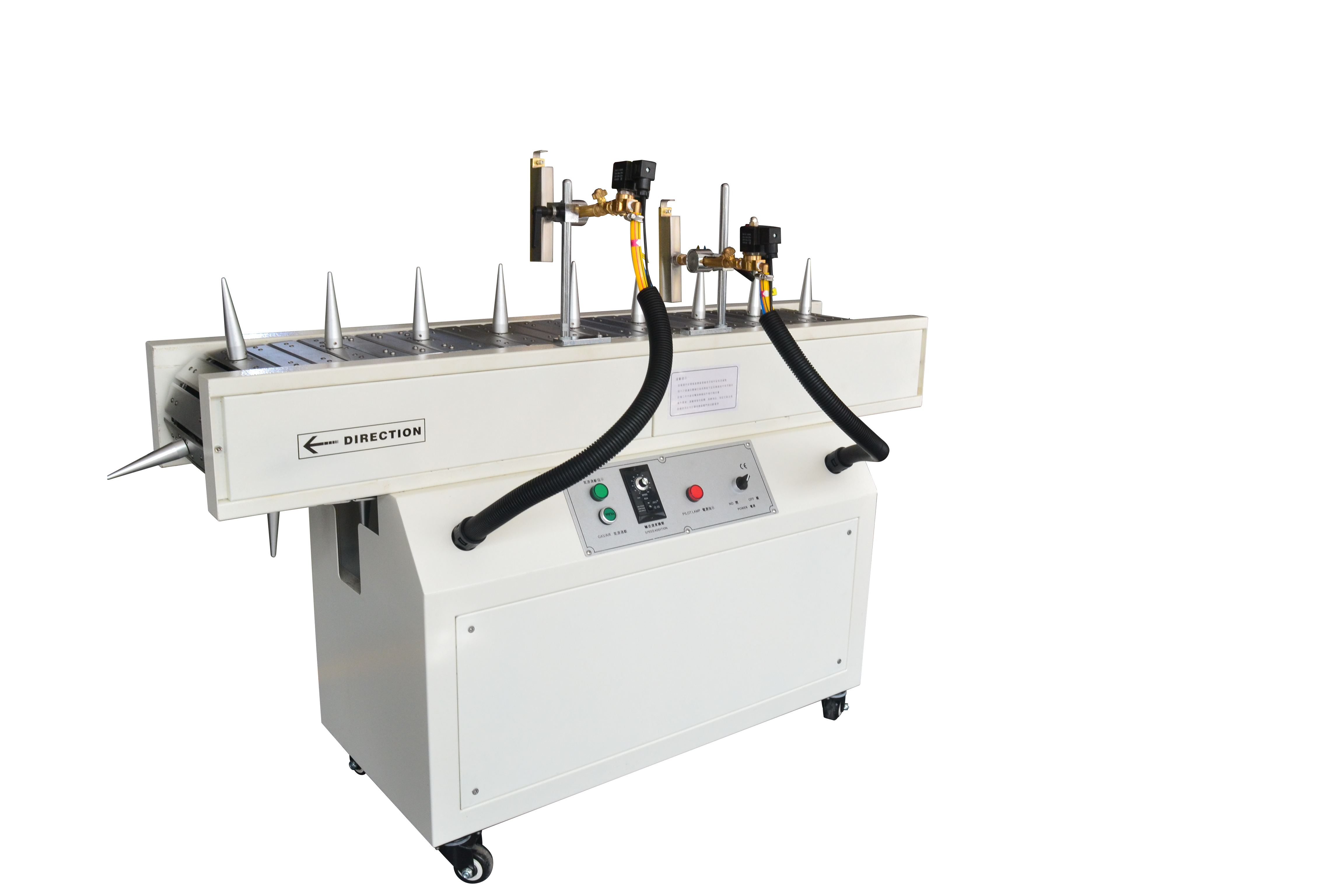

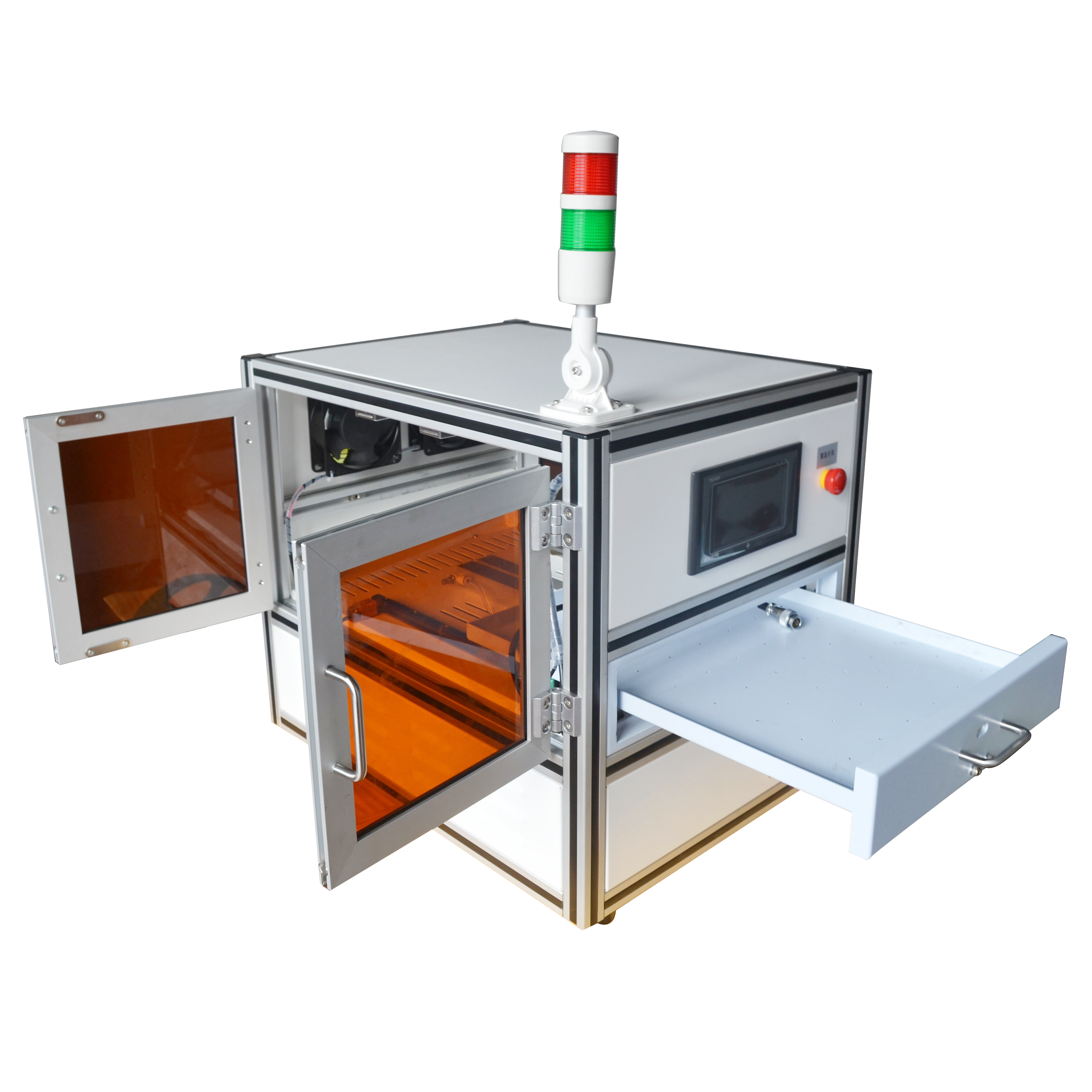

Scope of application

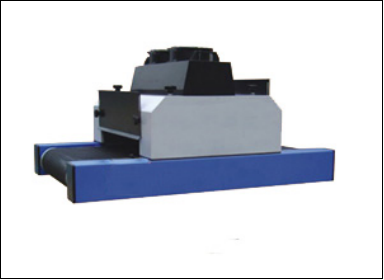

This product is mainly used for flame treatment on the surface of various bottles and cylindrical PE and PP plastic products. After the plastic products treated by this machine are printed, the ink can be more firmly attached to the printed objects.

Main parameters

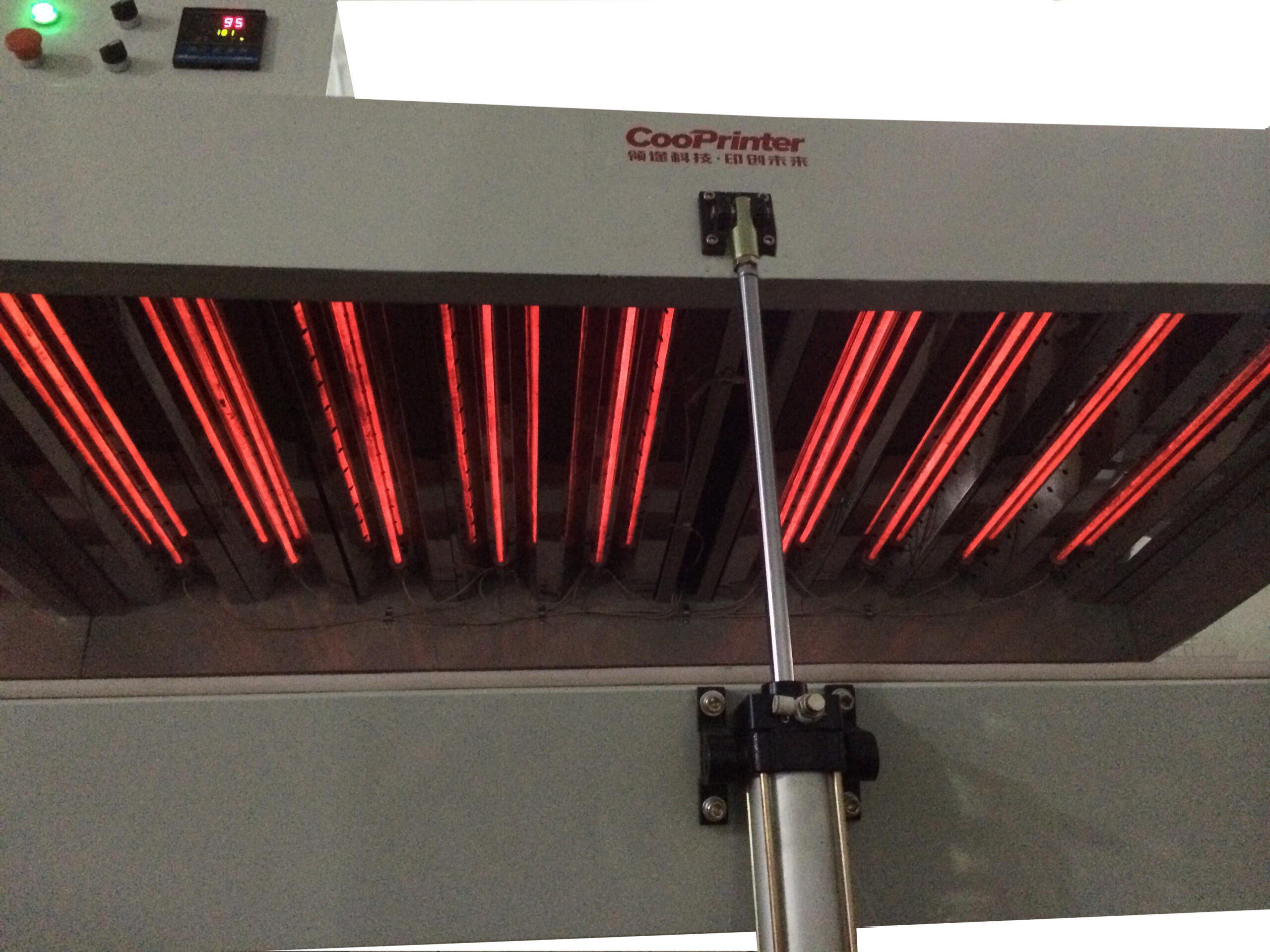

| Model | 200HYflame treatment machine | flame width | 25–250mm |

| Flame processor fuel | liquefied petroleum gas | ombustion-supporting | gas compressed air 8KGf/CM2 |

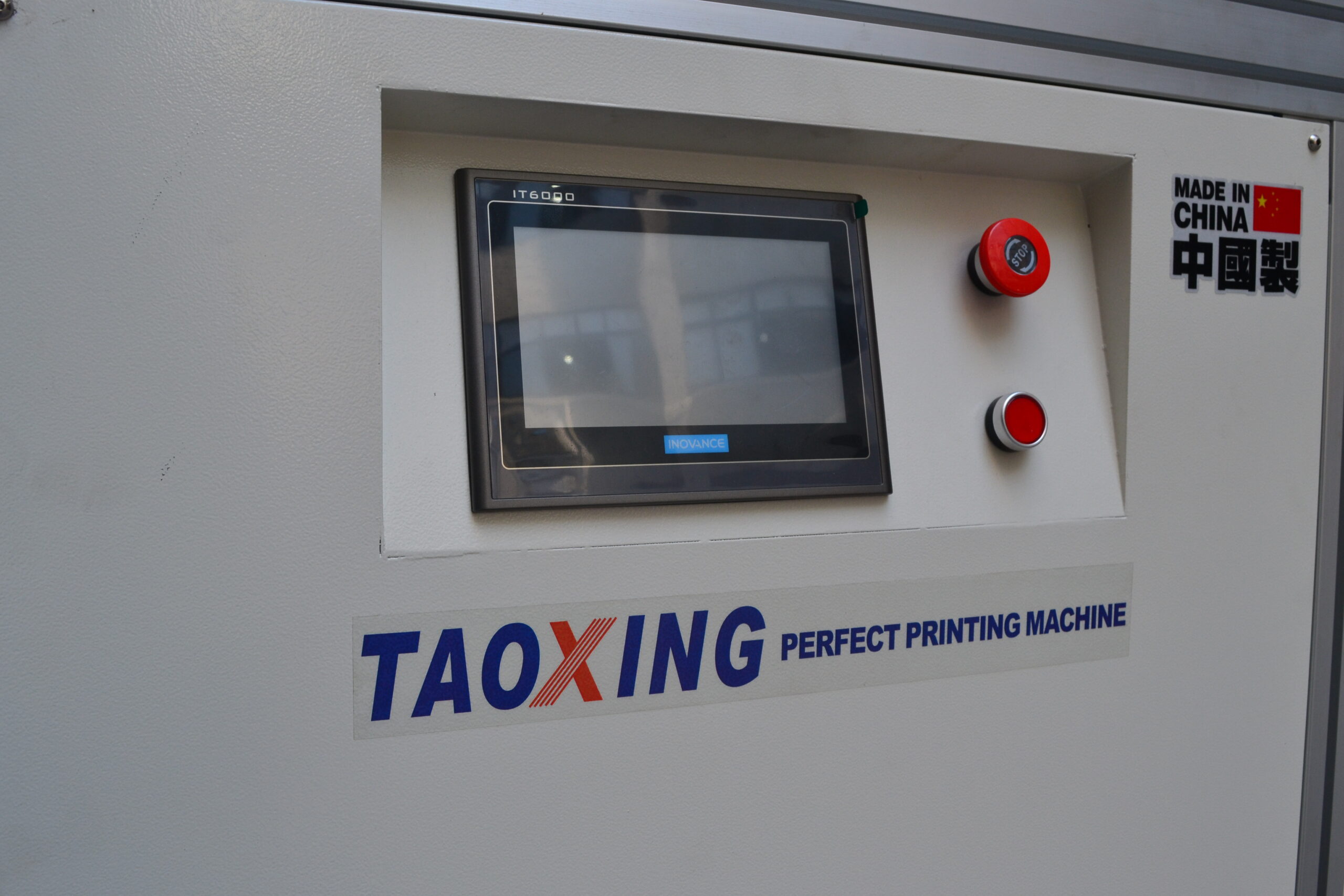

| Power supply | 220V/50Hz | Speed regulation | electronic stepless speed regulation |

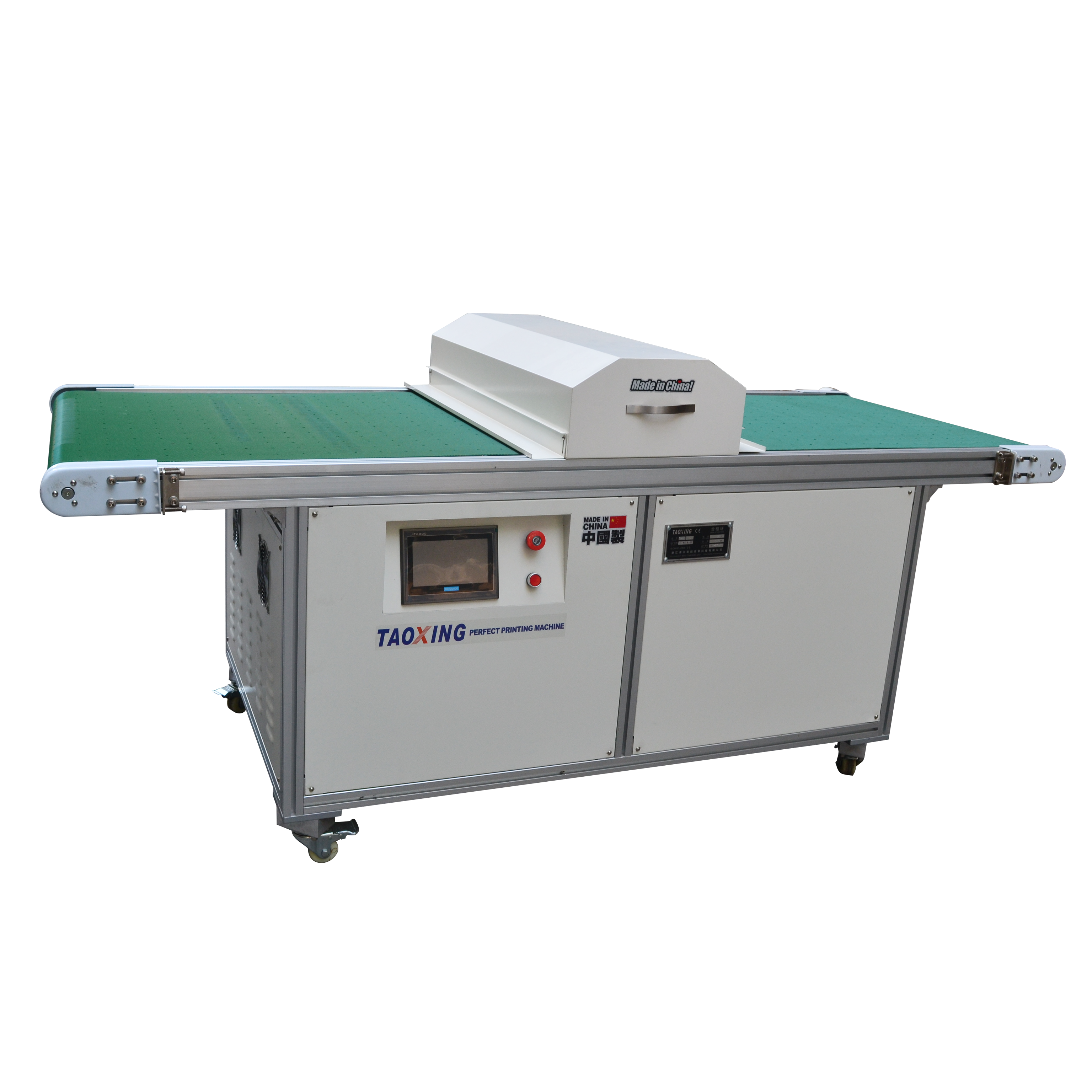

| Conveyor belt speed | 0-10m/min | Dimensions | 2200×1200×700 mm |

Main performance

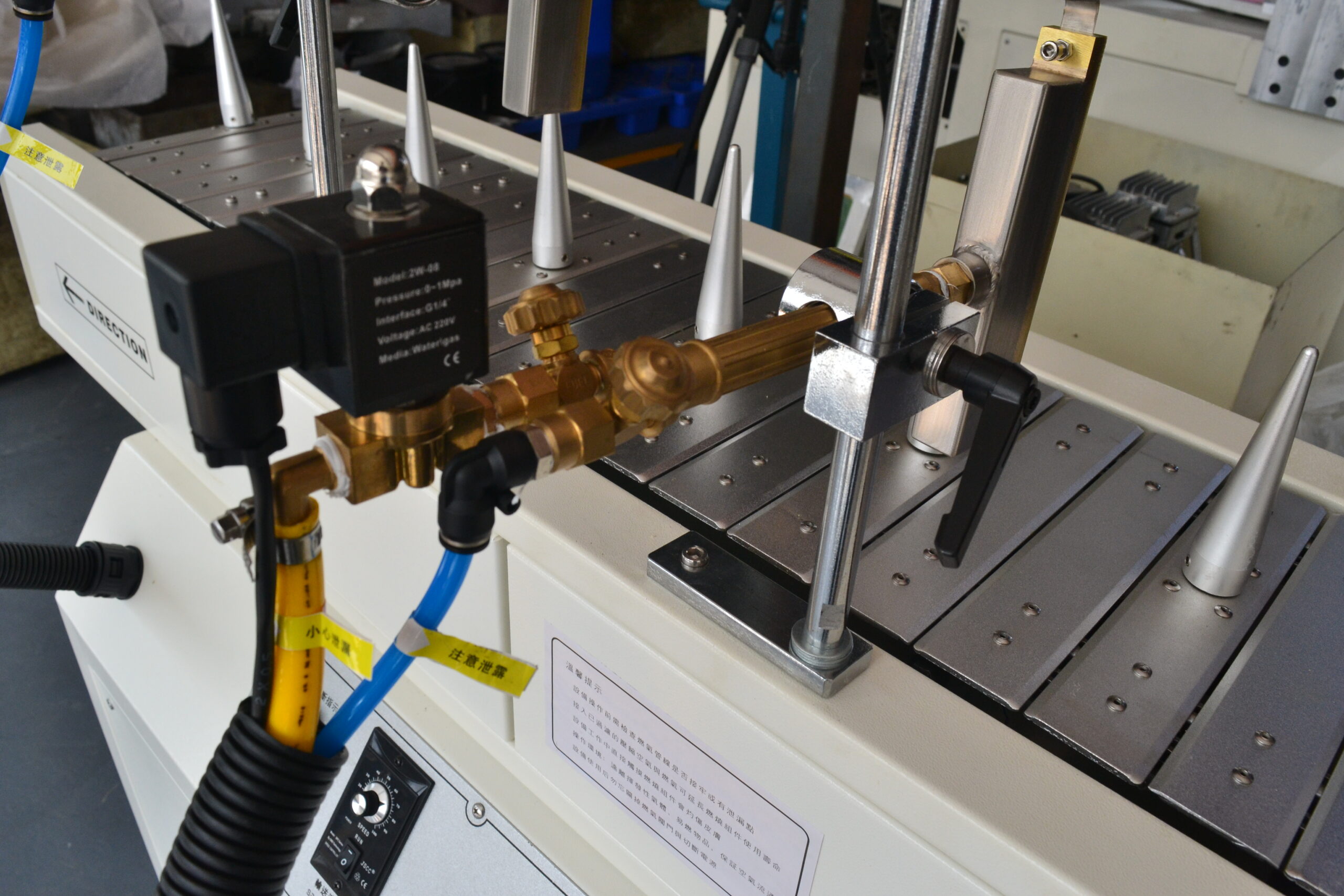

1 This machine is equipped with a universal conical support, which can meet the requirements of general bottle mouths, and can be matched with special sizes.

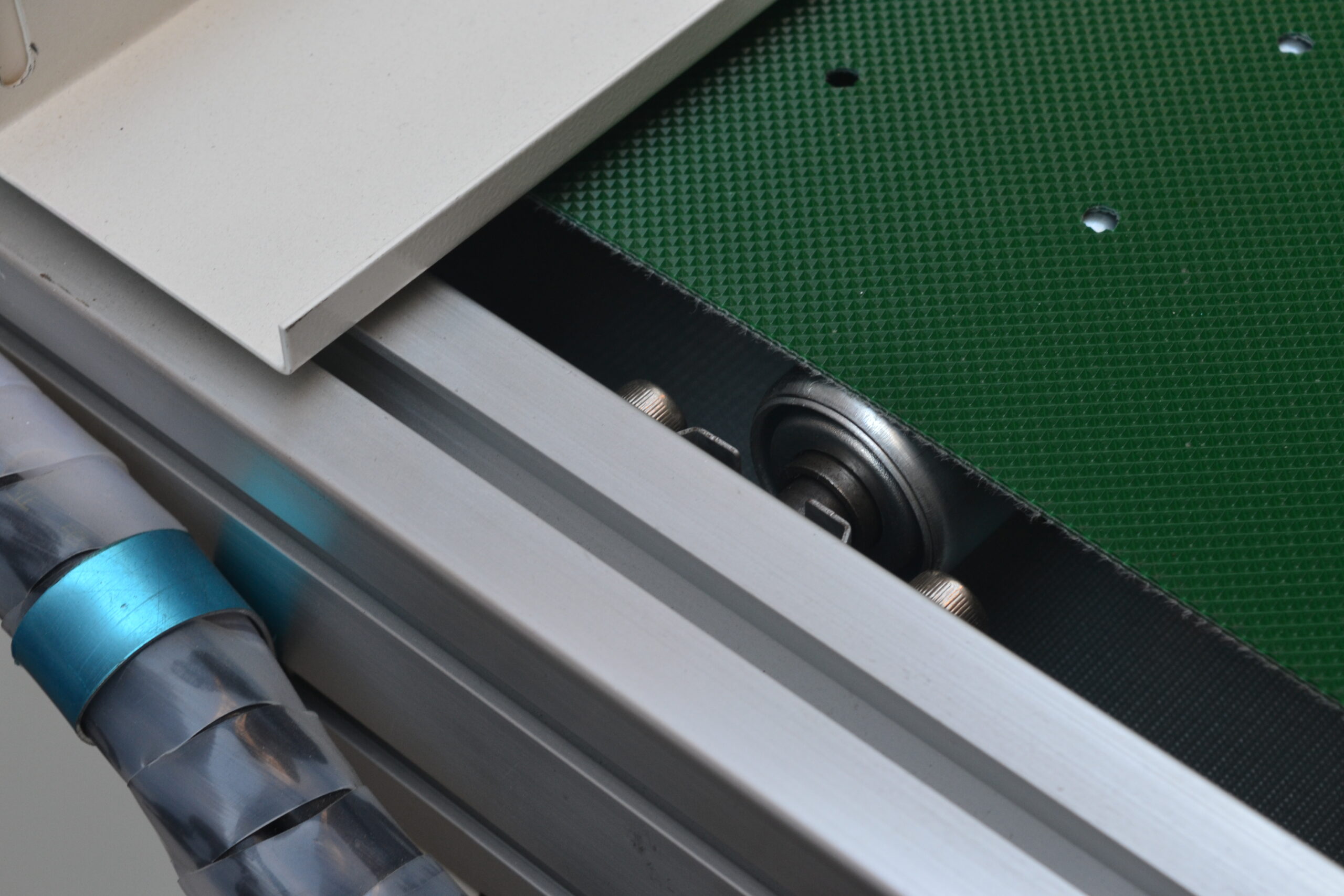

2 The conveying part of the conveyor belt adopts a micro-speed regulating motor, and the speed is adjusted by means of stepless speed regulation to adapt to the different requirements of different workpieces.

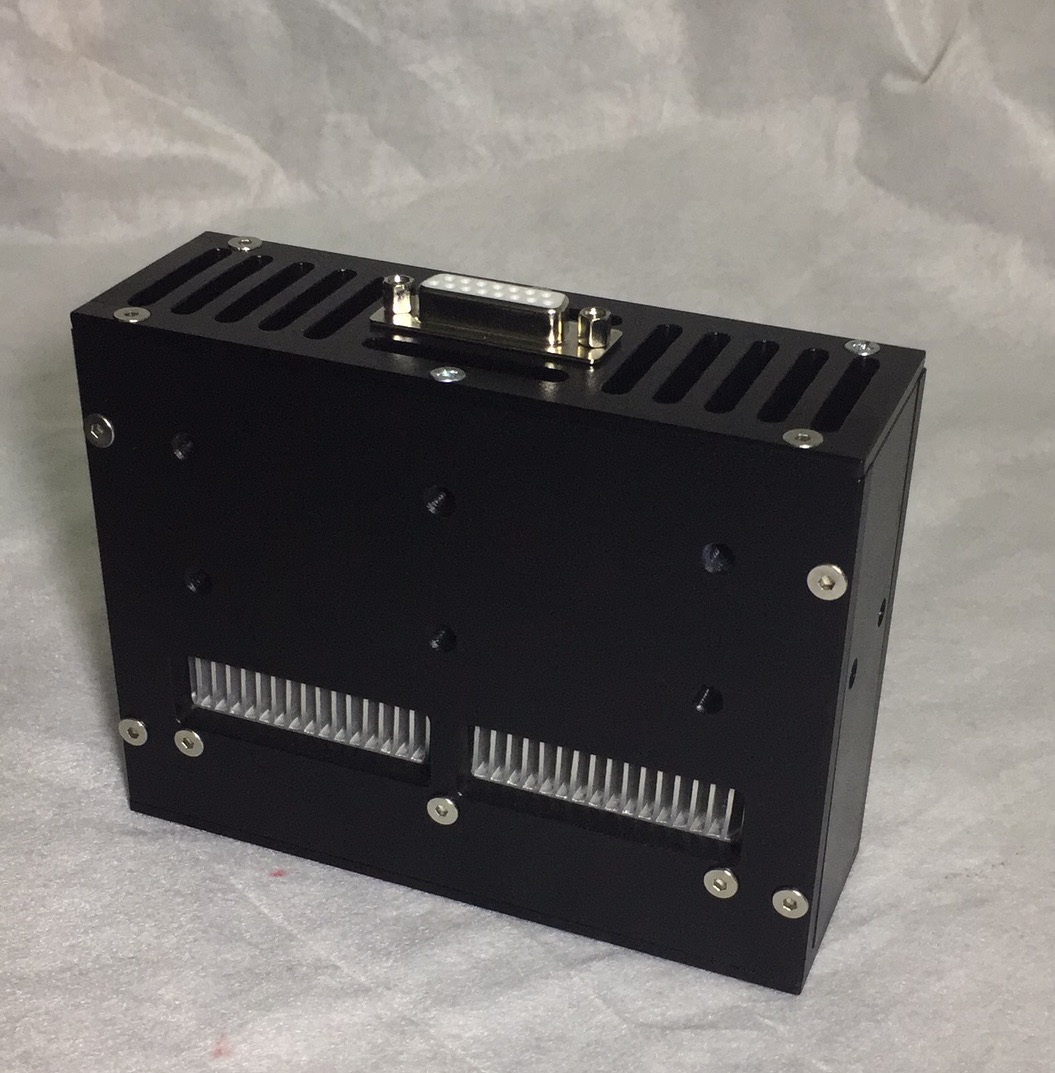

3 The design of the flame nozzle and the confluence is advanced and unique, and the fuel utilization efficiency is high, which is an energy-saving product.

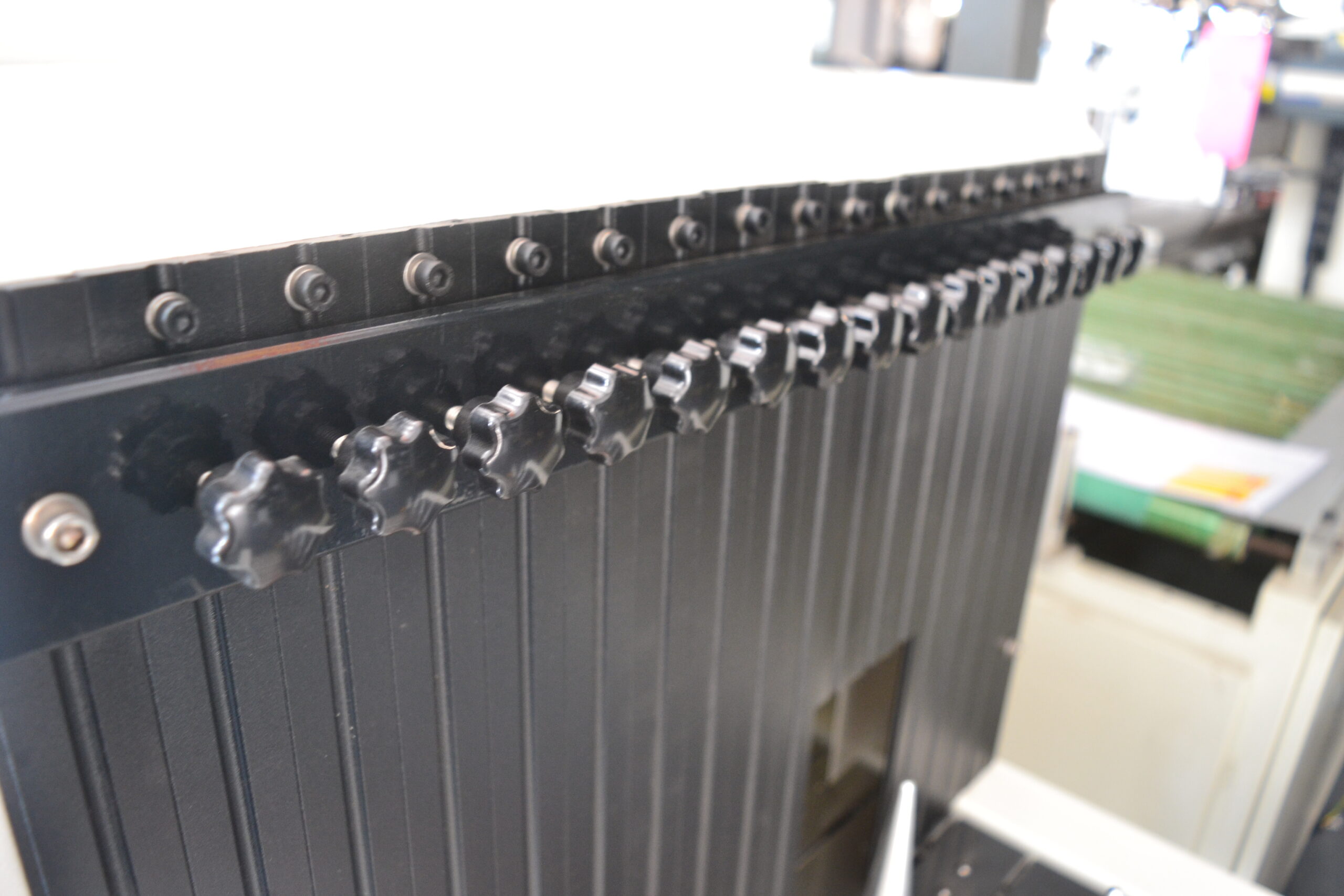

4 Electroplated aluminum alloy grooves, conical supports, and bright blue-plated chain plates make the machine more beautiful and suitable.

5 The whole machine has novel structure, reasonable design, convenient operation, and the bottom is equipped with movable casters, which is convenient to move.