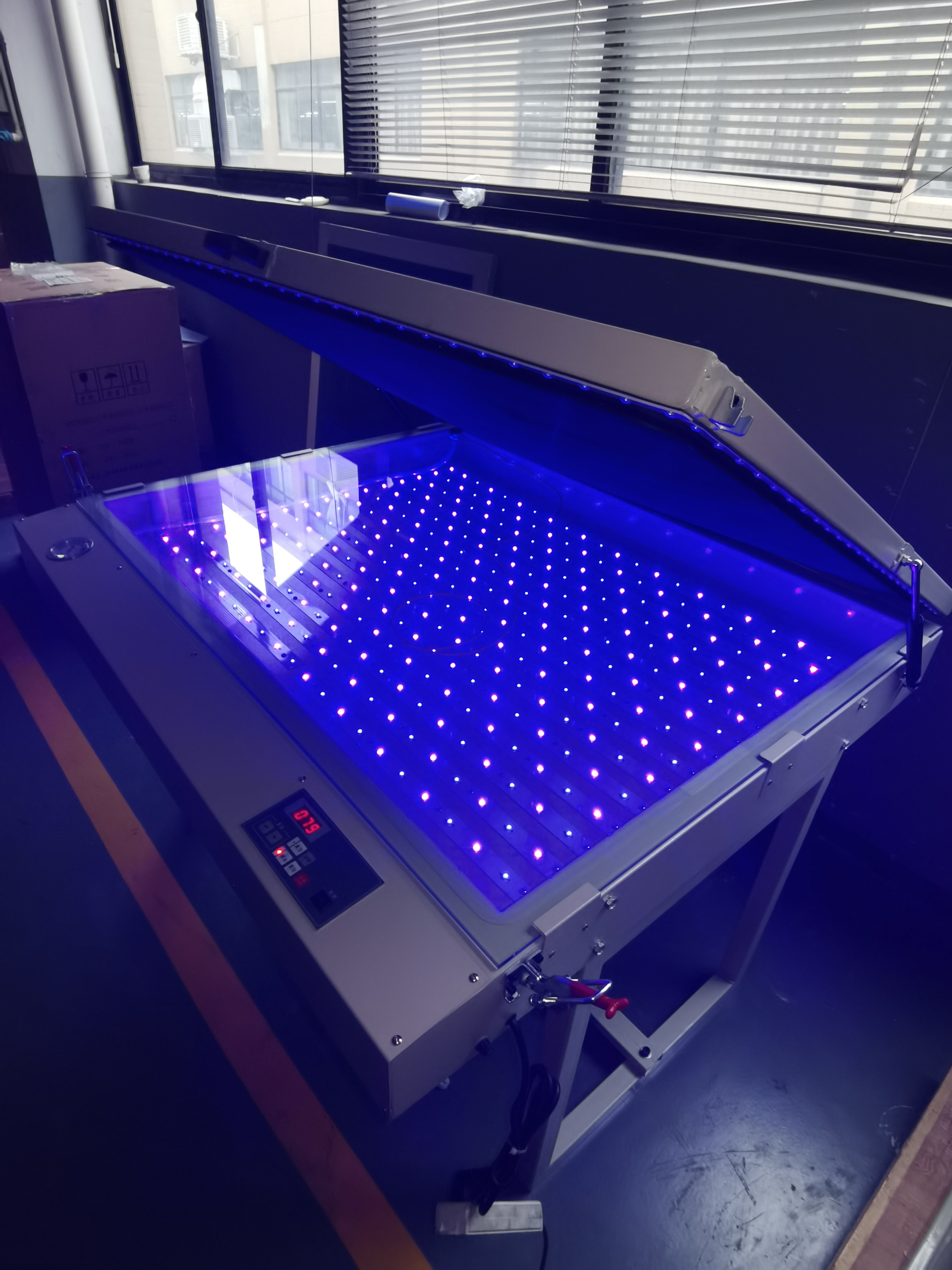

Scope of application:

It is suitable for drawing various mesh yarns such as high-Newton steel mesh, polyester mesh, composite mesh and high-precision mesh.

Main parameters

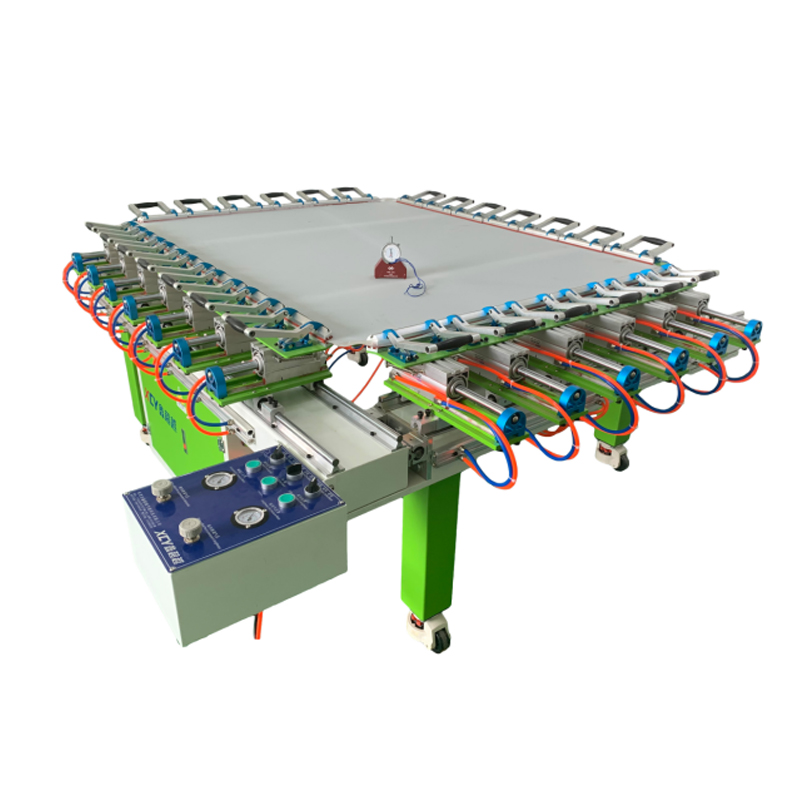

| Model specification | 1200×1500 |

| Maximum drawing area | 1200×1500mm |

| Unilateral stroke | 100mm |

| Maximum tension | 50N |

| Working air pressure | 3KG |

| Dimensions | 2200×2500 |

| Netting cylinder stroke | Ø63×100mm

Ø63×150mm |

Main performance

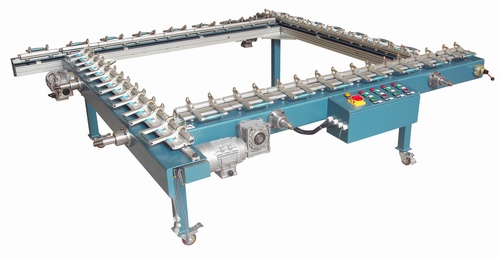

1. The girders are made of 200×100 special square tubes, and the girders can withstand a tension of up to 50 Newtons without deformation.

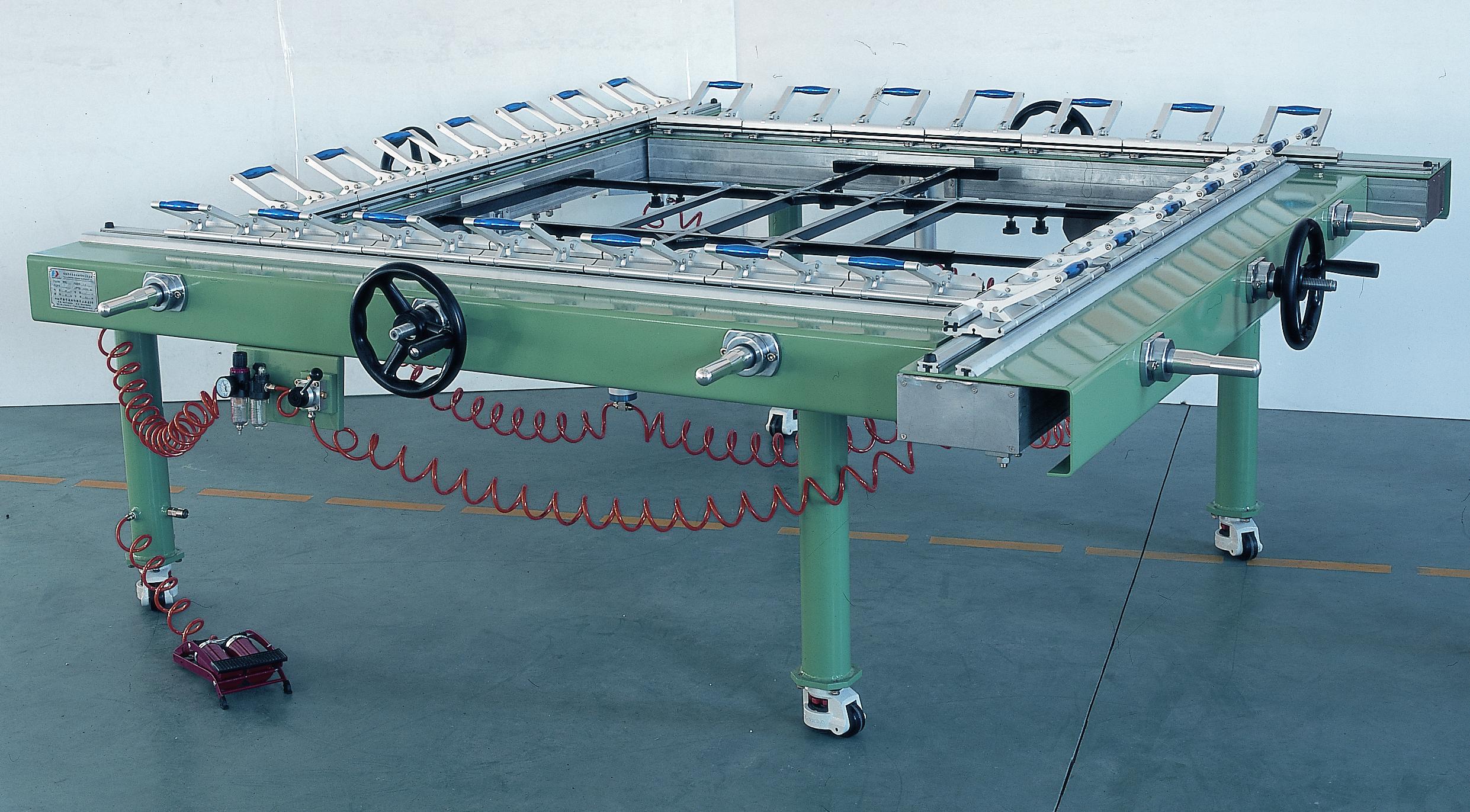

2. The four sides are telescopic, and the linear guide rail is designed to shrink.

3. The chuck adopts a patented product, the rubber does not need to be glued tightly, and the dovetail groove is used to match the mold.

4. The inner pad of the chuck is attached with imported rubber strips, which does not fall off, does not damage the mesh, and does not return the mesh.

5. The chuck base is designed with linear guide rail, and each chuck is installed with 3 linear bearings, which makes the chuck stable and precise.

6. 7 chucks are designed in the long direction (1500mm), a single jaw is 200mm long, and 6 chucks are designed in the width direction (1200mm), and a single jaw is 195mm long.

7. Two sets of control systems are designed: one controls the pulling net, the other controls the top net, so that the air pressure can be adjusted.

8. Design 6 top net cylinders.

9. Equipped with 2 rotating chucks on each side, the tension of the screen can be adjusted according to the tension of the mesh, so that the force of the mesh is more balanced.

the characteristics of the pneumatic mesh drawing machine and others:

1. Suitable for all kinds of mesh; such as stainless steel mesh, polyester mesh, Japanese NBC mesh and other domestic or imported mesh;

2. After the tension of the first mesh of the same type of mesh is adjusted and the air pressure is set, the tension of the mesh is not measured by the tension meter in the subsequent sequence, and the tension remains unchanged;

3. The design tension is large, the tension uniformity at each point is within ±0.5N, and the maximum tension is 60N. The tension can be adjusted according to the tension of the mesh, and it is very convenient to adjust the tension;

4. It is easy to operate, and the net can be laid casually when laying the net. It is not necessary to lay the angle of other types of netting machines. It takes a long time to adjust the balance of the pulling force. In the process of adjusting the tension, the tension meter is often bumped or the mesh is often broken, which can only lower the limit tension of the mesh. The machine can exceed 3-5N of the ultimate tension of the mesh, and it only takes a few minutes to pull the mesh once.

5. In the operation of pulling the net, the current many kinds of net pulling machines are all pulling the net by hand on one side, the operator is very hard, and it needs a master with strong professional skills and strength, and the salary is also high. Anyone can operate the precision pneumatic netting machine. The operation technology is simple and fast. One person can operate 3 to 4 pneumatic netting machines, which greatly saves costs and improves efficiency.

6. The machine has high economic benefits. Compared with other models, it can pull more than half of the screen plates every day. The yarn width can be selected from several specifications. The shrinking size of the machine can be used to prepare different specifications of mesh yarns according to different screen frames. Generally, the time and mesh yarn saved by this machine can recover the investment cost within 2 to 3 months.

7. The basic structure of the machine: the machine has size specifications, and can also be customized. There are two types: one is designed for tension below 45N, the other is designed for tension below 60N, the length of the chuck is 170-200mm, and the cylinder adopts 50 type, the drawing stroke is prepared according to different specifications, the drawing air pressure is 2.5 to 3.5 kg, and a small air pump is sufficient. Each cylinder is designed with a dovetail groove as a guide rail, which is wear-resistant and stable. The chuck seat adopts linear guides and linear guides. The bearing does not change shape when the net is drawn, the levelness measurement tension is very accurate, the clamping mouth adopts adjustable pressure, and the glue adopts the shape of silicone strip to design double dovetail grooves, which does not need glue and will not age, and will not harden in winter. (The phenomenon of hardening leads to breaking the mesh), the machine is equipped with imported high-precision adjustment valves for air pressure, which can be adjusted horizontally and vertically, so that the high-end mesh can be drawn beyond the limit tension of 3 to 5N.