This automatic laminating machine is a pre-coating laminating equipment developed by our company according to market needs. This machine can complete the two processes of lamination and slitting at one time, and is equipped with an anti-curling device to protect the thin paper from curling after laminating and slitting. This machine uses pre-coated film as lamination material, which can be widely used for lamination of packaging bags, books, magazines, drawings, maps and other products. The product after lamination has the characteristics of waterproof, durable, clear pattern and strong three-dimensional sense.

YBFM-920 Anti-curling automatic slitting hydraulic semi-automatic laminating machine

Model YBFM-920

| Model | YBFM-920 |

| Maximum lamination width | 880mm |

| Paper thickness | 125-500g/㎡ |

| Minimum format | 300*400mm |

| Laminating speed | 0-30m/min |

| Lamination temperature | 130° |

| Total power | 15kw |

| Power | 380/50HZ |

| Dimensions | 2600*1600*1600mm |

| Machine weight | 1500KG |

Structure and configuration

1. Manual feeding, automatic feeding of conveyor belt,

2. The baffle of the paper feeding table can be adjusted according to the width of the paper.

3. The photoelectric stacking positioner can automatically control the length of the overlap between the sheets (optional).

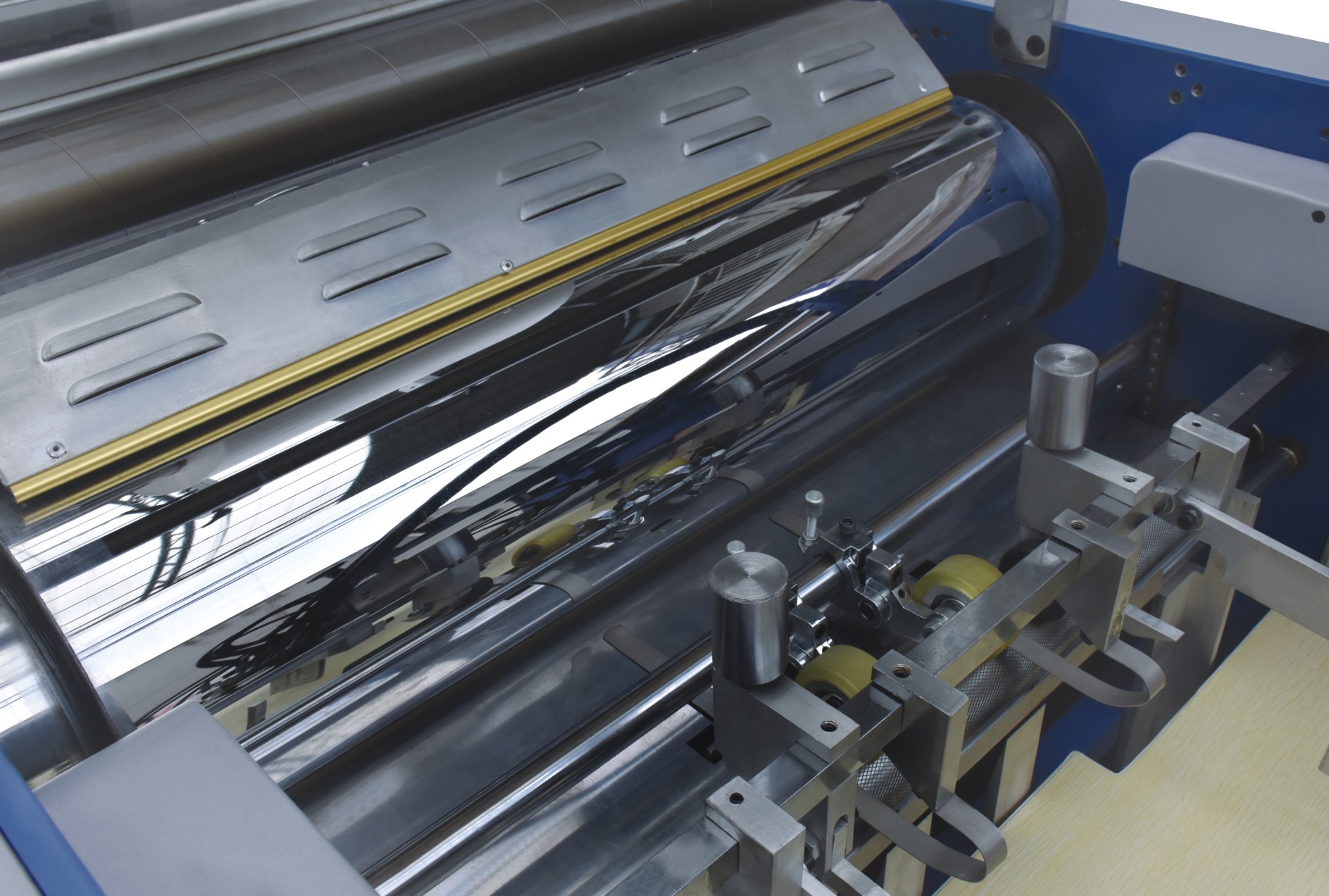

4. Heating method: the heat transfer oil heats the drum, the heating temperature is uniform, and the temperature can be adjusted according to the lamination requirements.

5. Pressurization method: automatic pressurization, and the pressure can be adjusted according to the requirements of laminating.

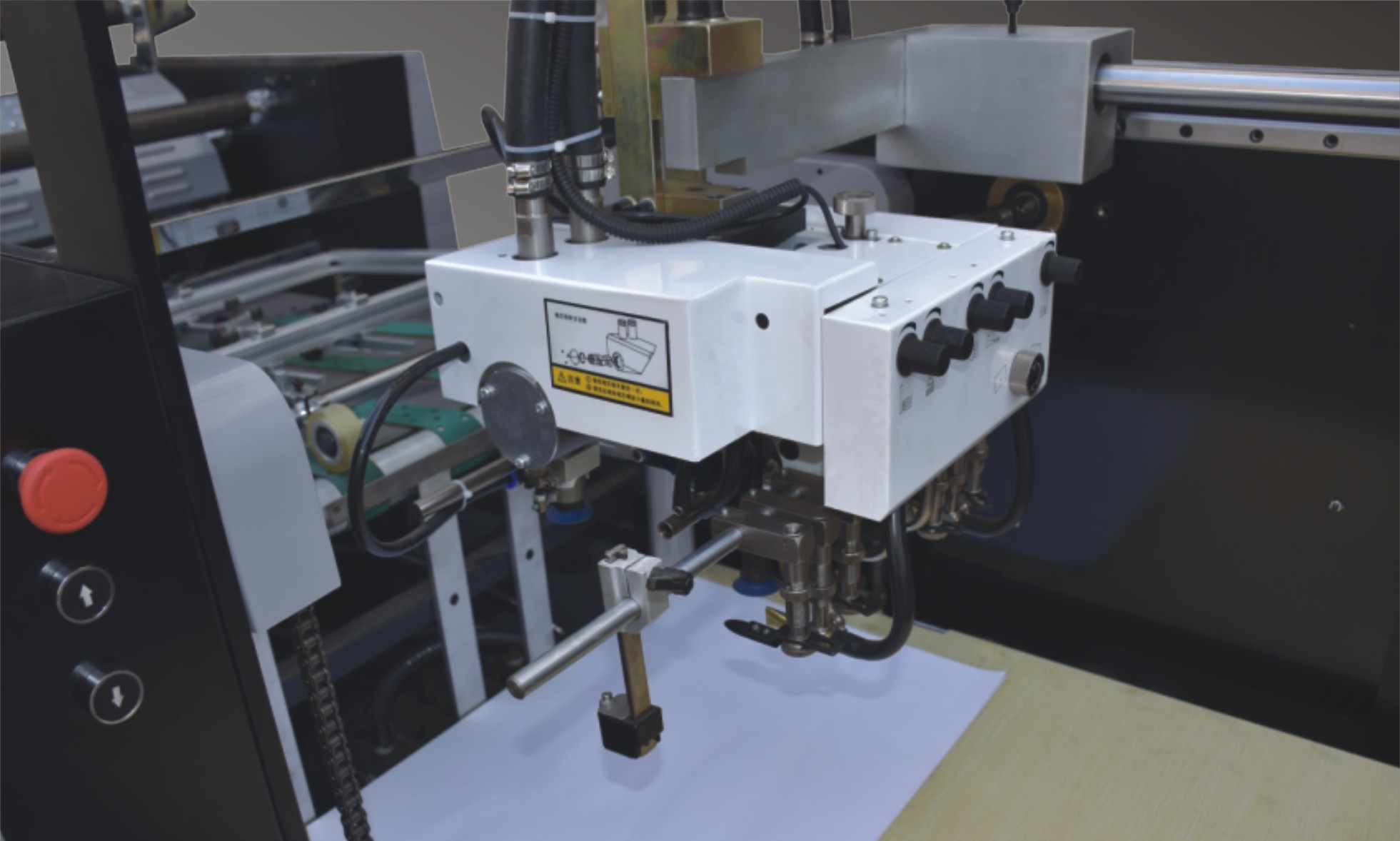

6. The punching hob can roll out a row of small holes on the edge of the film to smoothly realize automatic slitting.

7. Anti-curve device: After laminating, the paper is shaped by the anti-curve device, and after slitting, the paper is no longer curled.

8. The film slitting knife can cut wide and long film rolls (relative to paper specifications). The excess film remains on the film release shaft after cutting.

9. Automatic slitting system: Adjust the slitting position according to the size of the paper to realize automatic slitting of laminated paper.

10. Delivery table: The slitted paper will be sent to the delivery table. The table height can be adjusted according to actual needs.

11. The integrated structure design makes the equipment run more smoothly and prolongs the service life of the equipment.

12. Schneider inverter realizes infinitely variable speed. Users can change the speed of the equipment in an instant and ensure smooth operation of the equipment.