YFMB-540 Semi-automatic Film Laminator

Contact Us

Inquiry

Specifications:

| Model | YFMB-540 |

| Max Paper Size | 520mm |

| Paper Thickness | 100-500g/m2 |

| Laminating Speed | 0-25m/min |

| Power | 9kw |

| Total Weight | 700kg |

| Overall Dimensions | 3300x1150x1450mm |

| Heating roller diameter | 216mm |

| Packing Size | 1.8*1.45*1.5m (3.9CBM) |

Features of the machine:

- YFMB-540series thermal laminator is the most advanced manual feeding laminating equipment. This machine is with the characters of high-automation, easy-operation, safety and stability. It can widely adopt in carton packaging, label making and digital printing product. It’s the good choice for large and medium sized printing house

Features By Part:

- High precision of chrome plated heating roller is equipped with built-in oil heating system, which has excellent performance to temperature control. The laminating temperature is adjustable upon applications.Enlarged size of chromed heating roller is mounted with built in oil heating system which provides balanced laminating temperature and owns excellent temperature persistence.

- Pneumatic film unwinding system positions film.roll more accurately, and makes the loading and unloading of film roll and film unwinding tension much more convenient.Double sets of serrated perforating wheels provide different choices for different specifications of sheets and film.

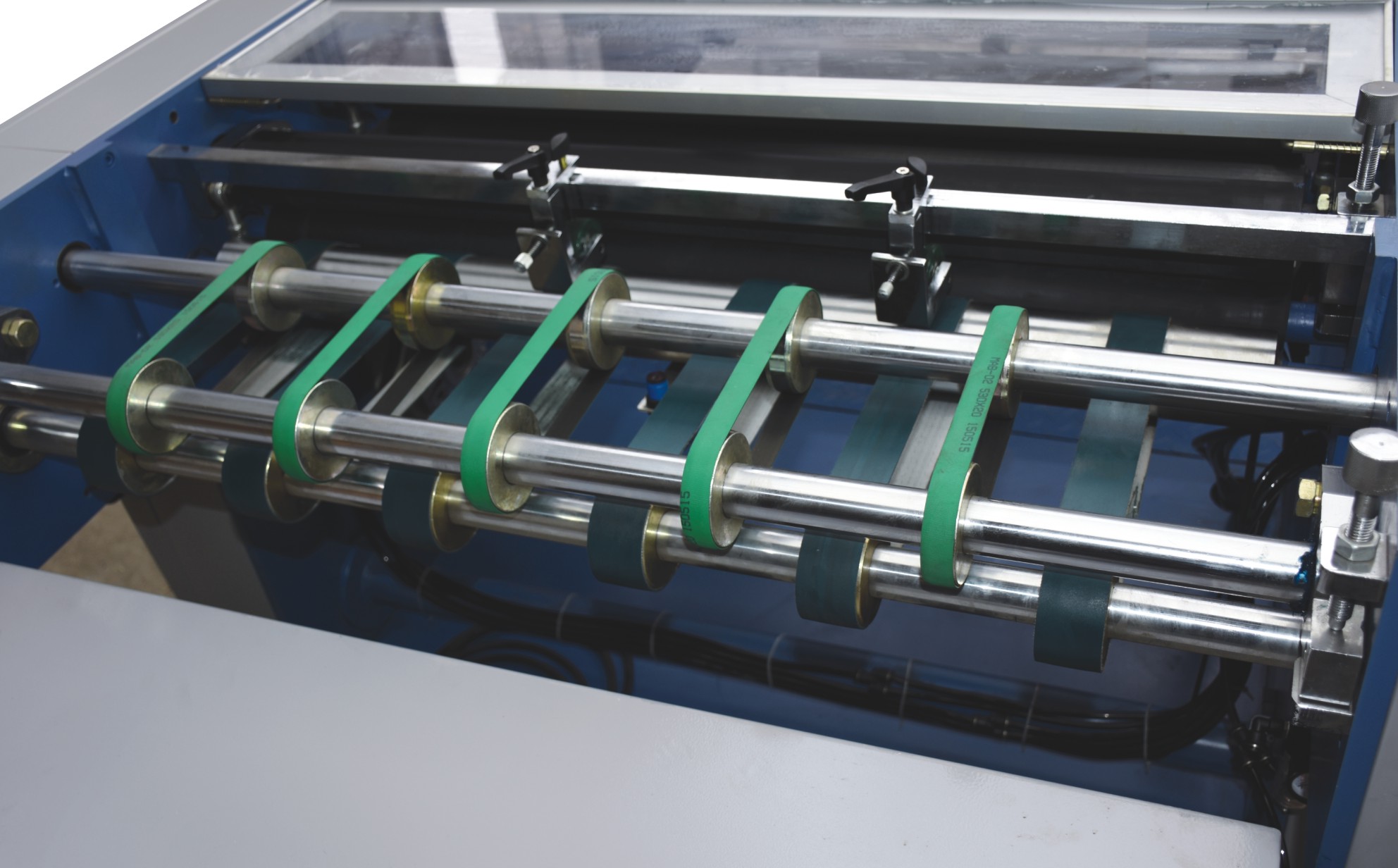

- Perfected traction adjusting system makes traction adjustment more convenient and efficient.

- Corrugating delivery system ensure paper collection more regular. Anti-curling device: whenpaper going through anti-curl device, the laminated paper shall be leveled at once and wont curve again after cutting

- Hydraulic pressuring system provides big and steady pressure to guarantee good laminating quality.

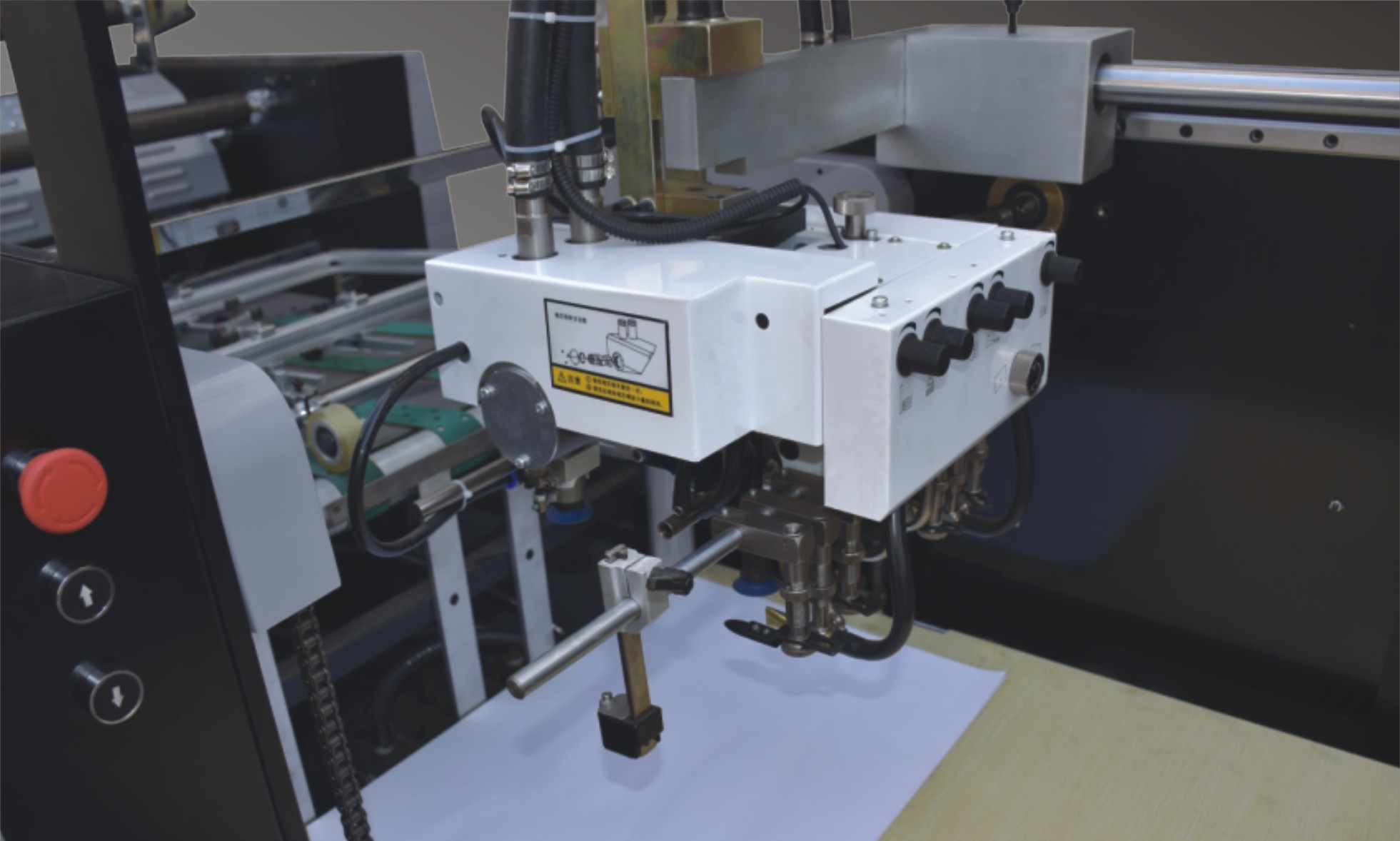

- Pneumatic cutting system realizes automatic paper cut as long as the operator inputs the workable paper size on the text screen.

Air expansion shaft releases film, and positioning accuracy,also makes the loading and unloading of film roll more convenient.

Configuration:

| NO. | Name | MODEL | QTY | REMARKS |

| 1 | PLC | 40MT | 1 | Inovance |

| 2 | touch screen | 6070T | 1 | WEILUN |

| 3 | Servo drive | IS5-9S2R8/400W | 1 | Inovance |

| 4 | frequency changer | 2.2KW | 1 | PNEUMATIC |

| frequency changer | 4KW | 1 | HYDRAULIC PREASURE | |

| 5 | miniature circuit breaker | DZ60-47/C32A | 1 | SCHNEIDER |

| 6 | miniature circuit breaker | DZ60-47/C10 | 2 | SCHNEIDER |

| 7 | alternating current contactor | 1210/220V | 6 | SCHNEIDER |

| 8 | alternating current contactor | 3210/220V | 1 | SCHNEIDER |

| 9 | intermediate relay | MY2N-J | 9 | OMRON |

| 10 | Solid state contactor | J25S25 | 2 | CHINA |

| 11 | Voltage heating module | 3PH60DA-H | 1 | WUXI |

| 12 | limit switch | YBLX-ME/8108 | 2 | SCHNEIDER |

| 13 | Pressure limit switch | ME-8111 | 1 | SCHNEIDER |

| 14 | Reflection type photoelectric switch | HE18-R2N/24V | 1 | OMRON |

| 15 | Square photoelectric switch type | E3Z | 1 | OMRON |

| 16 | photoelectric switch | DS30 | 1 | OMRON |

| 17 | proximity switch | BB-U202N/24V | 1 | OMRON |

| 18 | pilot lamp | XB2 | 1 | SCHNEIDER |

| 19 | Transfer switch | ZB2-BDZC | 4 | SCHNEIDER |

| 20 | stop switch | BS54C | 3 | SCHNEIDER |

| 21 | button switch | ZB2(Green、White、Red) | 2(Green)+1(white)+1(red) | SCHNEIDER |

| 22 | encoder | E6BZ-CW26C/1000R/24V | 1 | OMRON |

| 23 | Power Module | S-35-24 | 1 | TAIWANG |

| 24 | temperature-sensing wire | 1-model | 1 | OMRON |

| 25 | thermograph | MXTG-6501 | 1 | OMRON |

| 26 | Switch contact | Normal open:ZBS-BZ101 | 10 | OMRON |

TaoXing Company Introduction

Taoxing automatic screen printing machine video compilation

Service / FAQ

Guarantee

① We provide comprehensive one-stop services, customer training and satisfied after sales services.

② Online support, video technical support for troubleshooting manufacturing problems, engineers are available to service oversea as necessary.

③ Sold enjoy one year of free equipment warranty and lifetime technical support.

Guarantee for Delivery

Safety and fast logistic ensures the goods are delivered on the right time

1. Packing: Plywood Case for Each Machine

2. Payment terms: T/T (50% deposit to start the production, 50% paid before delivery)

3. Delivery date:60 business days after received the payment.

4. Departure of port: By sea from Shanghai or Ningbo

5. Delivery means: By sea by land

A: We are a professional manufacturing factory specialize in printing equipment with more than 20 years experience, committed to supplying our customer top quality and dedication to the constant improvements of quality, reliability, productivity and the competitiveness of our products and services.

A: Please send us an inquiry directly. We need to get specific details, such as material, size, color, thickness, quantity, etc.

A: Yes, we have a professional technique team, we could produce the machine depends on your requirements.

A: We accept TT/LC/PAYPAL/Western union, every payment term we can discuss.

A: All Taoxing products carry up to a full year warranty. Supply wearing parts with favorable price and long term after-sales service. We believe in total customer satisfaction, aside from our no-hassle guarantee.

Screen printing was a technique first used by the Chinese almost 2000 years ago. It is widely used at home and abroad. Chinese printing machine market has already become the focal point of the world have opened up. We have teams of experienced technical experts and professionals providing most professional and just-in-time technical consults and services, timely supply of spare parts in place.

If you are still confused how to start printing work, don’t worry, contact us and we will help you out!! No mater you are a green hand, we will train you up-to-date technology skills, and keep an eye on your business opportunities. Our friendly and professional team that is able to handle all your inquiries whenever you need.