Scope of application

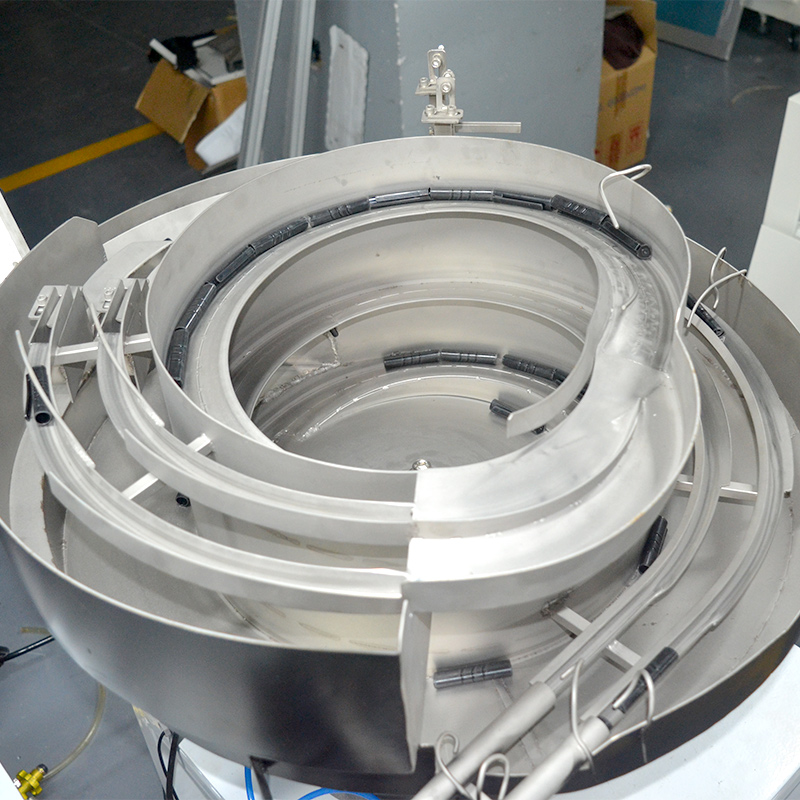

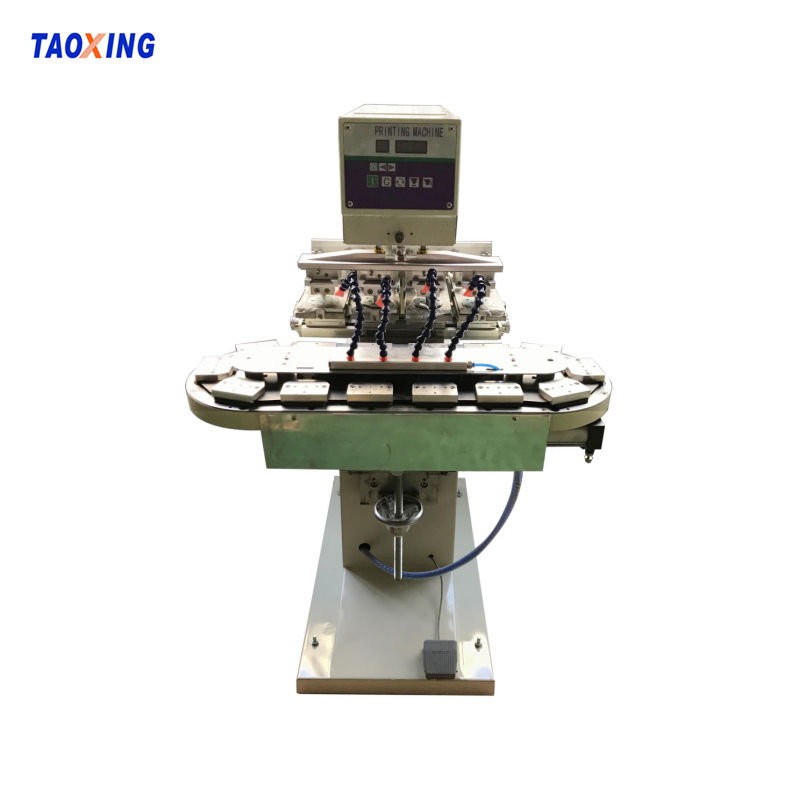

Suitable for special pad printing machine for scale printing in 10-24 inch pot

Main parameters

- 要参数

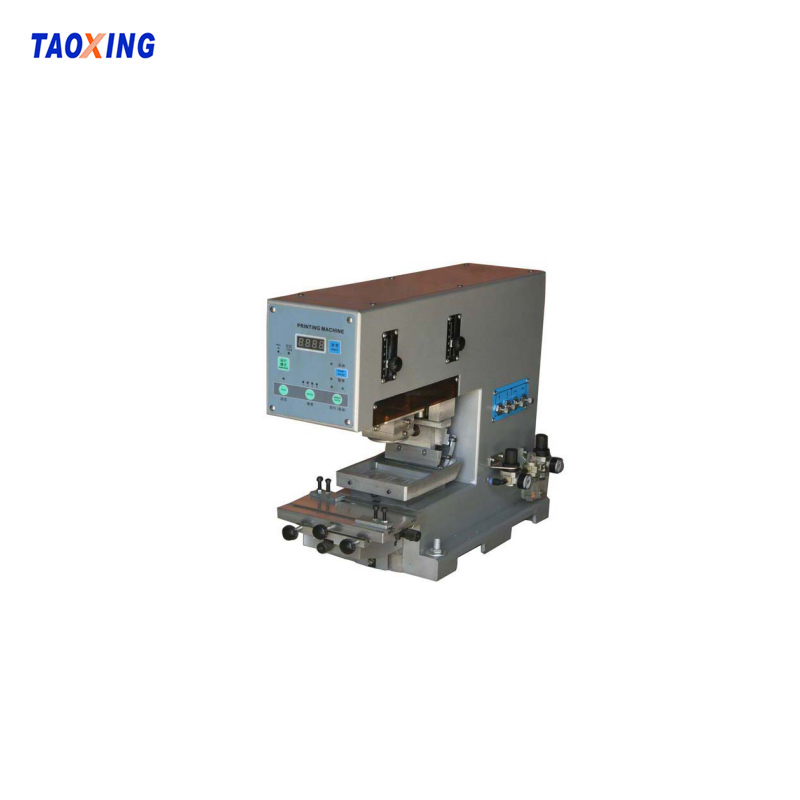

| Model | TXD–150–200 | Printing Thickness | 3-9bar |

|

max printing area |

50mm | power supply | 220V/50HZ/50W |

|

Size of printing table |

200mm | Steel plaste size | 150*150mm |

|

max size of screen frame |

1200 pcs/hr | Dimension | 1200*880*1770mm |

Main performance

①Microcomputer controls the operation of each function, which is simple and convenient to operate.

② Built-in four-digit automatic counter.

③The machine structure adopts high-quality aluminum alloy, which is light and strong.

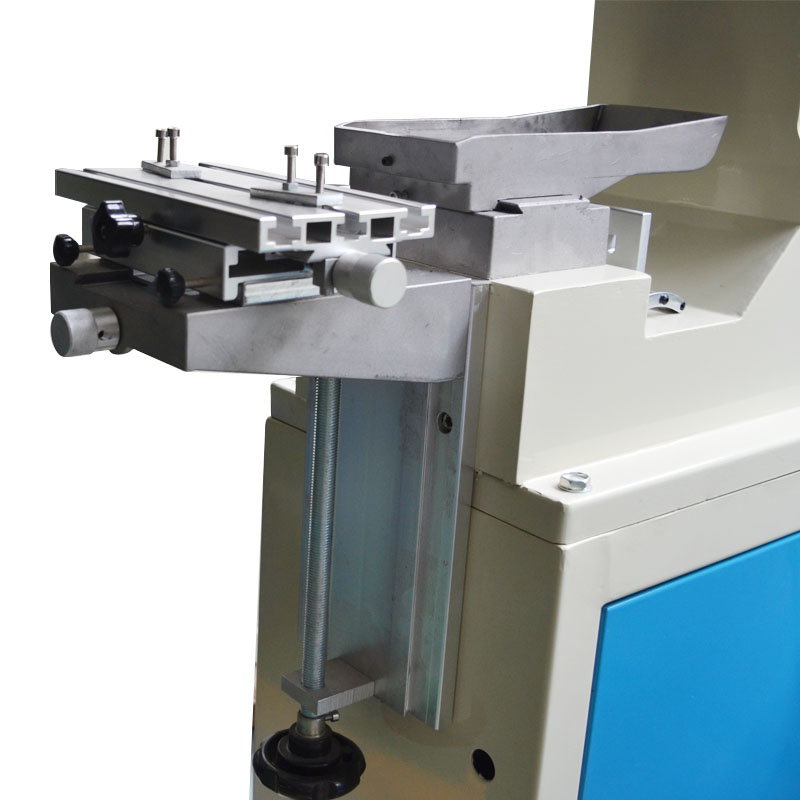

④The oil roller is inked, easy to assemble, disassemble and clean.

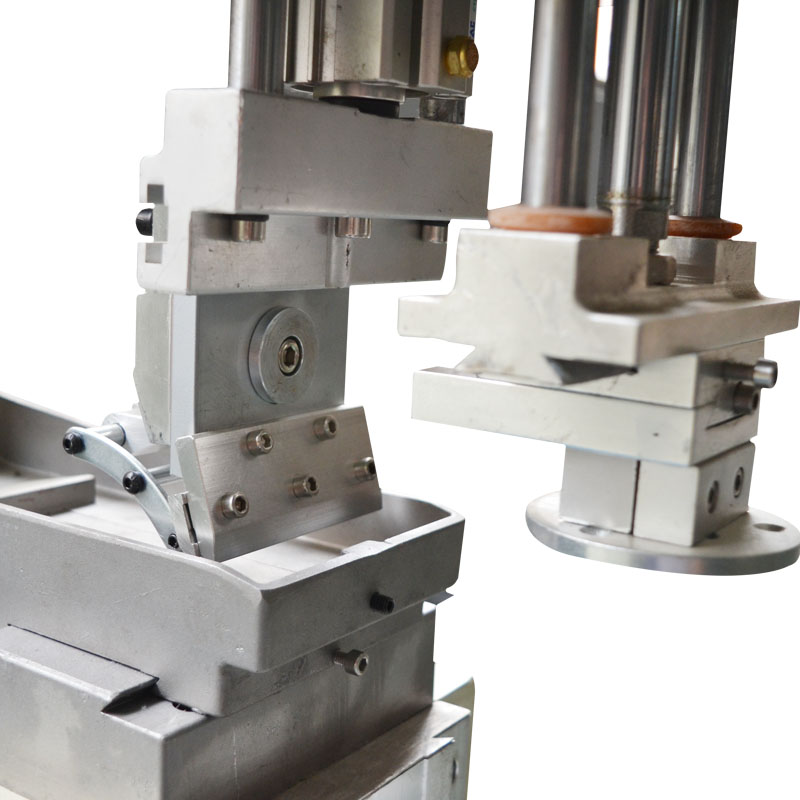

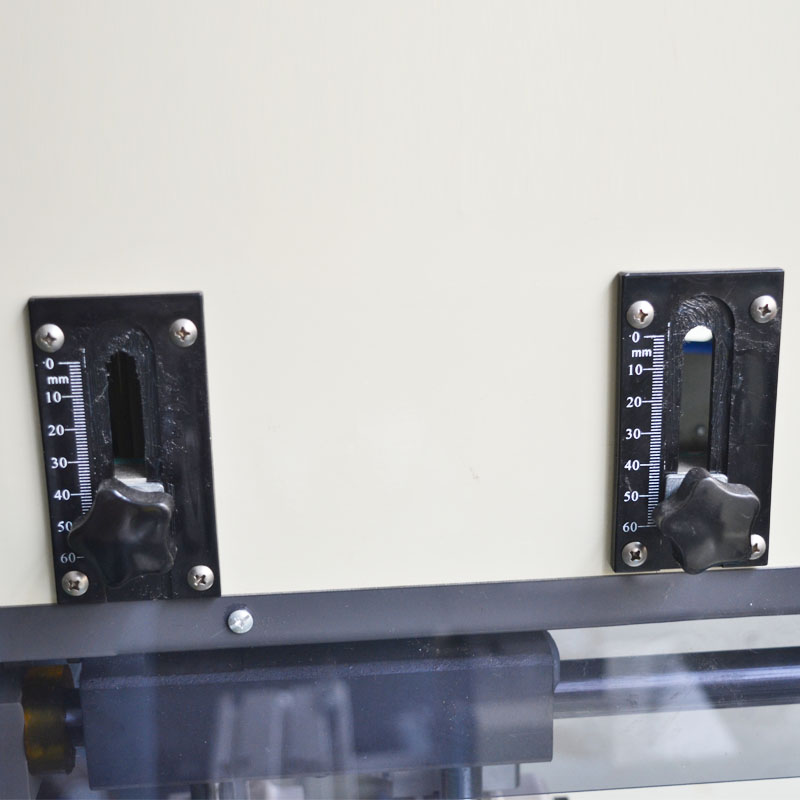

⑤Independent rubber head up and down stroke and speed adjustment.

⑥ Automatically balanced scraper, scraping ink cleanly.

⑦ It can be printed twice by sticking ink once in order to obtain larger printing ink.

⑧It can be empty before and after without falling off the glue head, preventing the ink from drying and solidifying when it stops for a while.

Machine maintenance

① Before going to work, clean up the sundries on the machine and wipe the machine clean. Lubricating grease should be added regularly to moving parts such as guide rails, guide posts, and bearings.

② The workpiece table is a key component that affects the printing quality. It prevents the impact of hard objects. During printing, the ink cannot be removed. Organic solvents such as Tianna water drip onto the work surface.

③ The electric control panel and buttons should be prevented from being damaged by direct or indirect contact with solvents such as Tianna water, boiled oil and water.

④ The frame paint is to keep the machine from rusting, to prevent damage caused by direct or indirect contact with solvents such as Tianna water, boiled oil and water.

⑤ Drain the sewage and dirt in the oil mist combiner in time. To prevent the pneumatic components from being fed into the normal operation, clean the cup body regularly, and add Peng 2 lubricating oil to the oil cup of the oil mist combiner.

⑥ When adjusting the restrictor valve, the tightening nut must be loosened before adjusting by hand. The handle screw on the machine is used for positioning. After firmly positioning, there is no need to tighten it with excessive force.

⑦ After get off work, turn off the power/air source, clean the wire mesh, and keep it properly. Dust/pressure/hard object piercing.